Plate Making machine

120000 INR/Piece

Product Details:

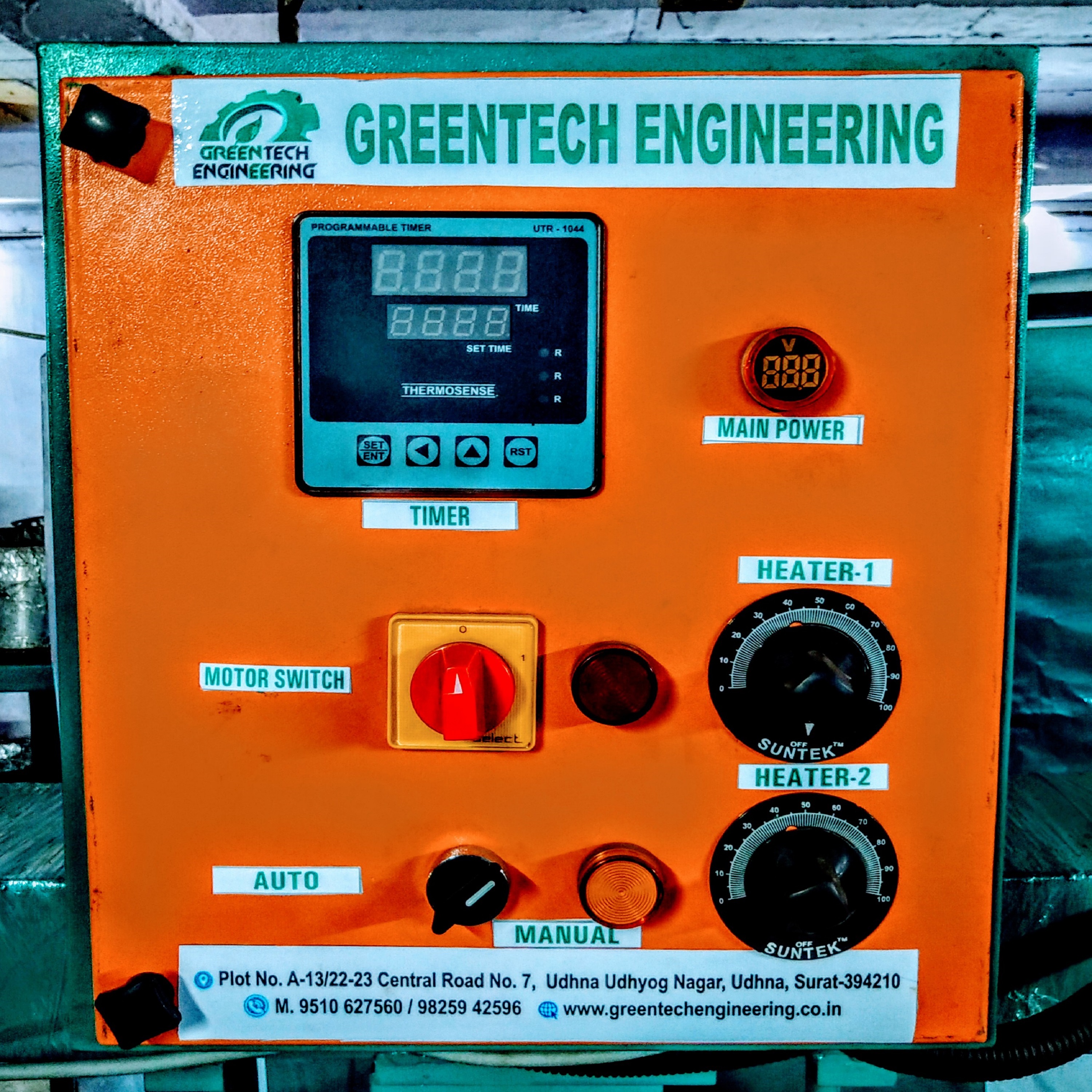

- Control System Human Machine Interface

- Warranty One year of Motor and Programmable Timer

- Click to View more

X

Plate Making machine Price And Quantity

- 120000 INR/Piece

- 01 Piece

Plate Making machine Product Specifications

- Human Machine Interface

- One year of Motor and Programmable Timer

Plate Making machine Trade Information

- 50-60 Piece Per Month

- 5-7 Days

- Yes

- If order is confirmed we will reimburse the sample cost

- All India

Product Description

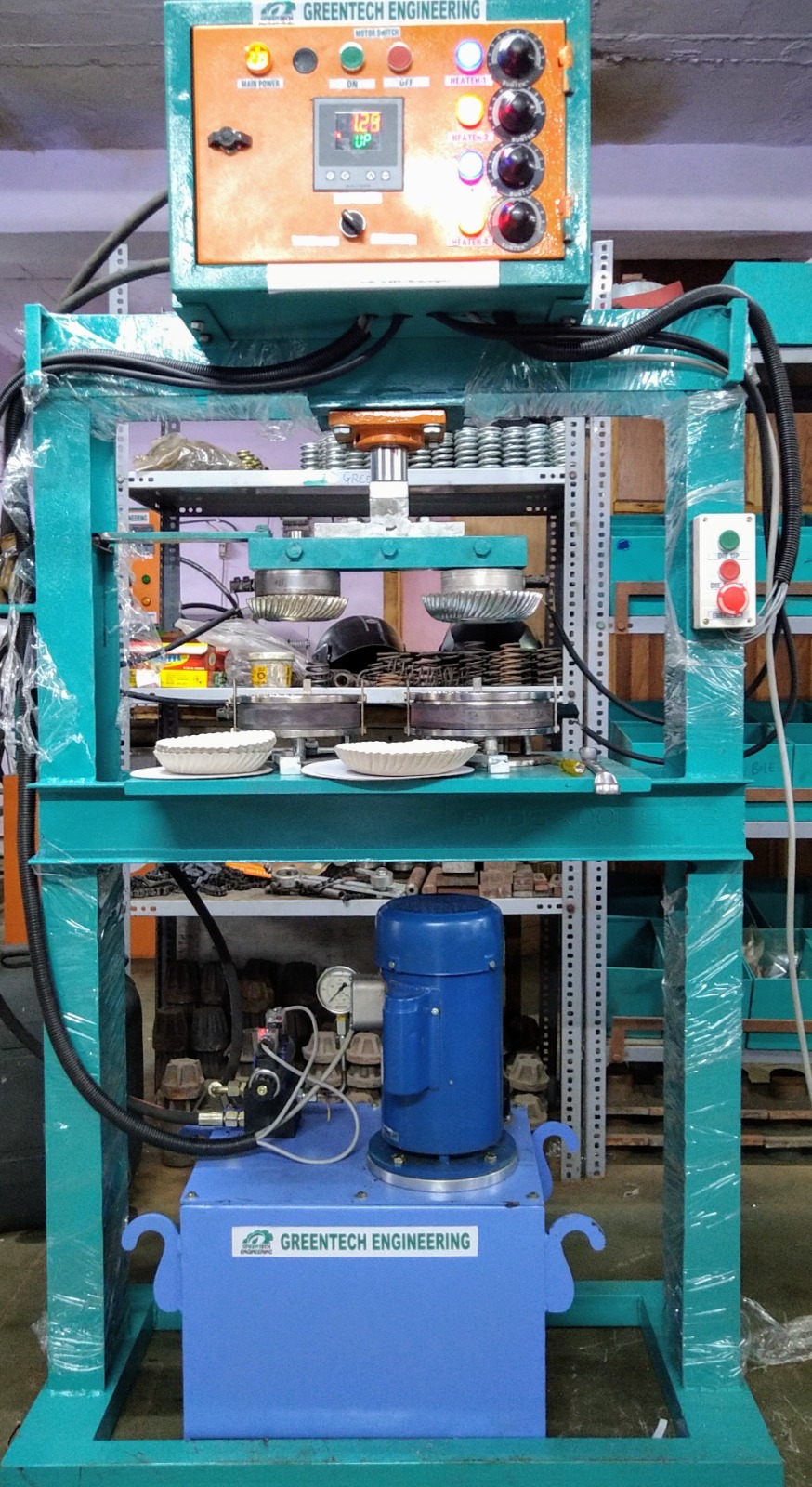

Technical Specifications

|

Model No. |

GT-P10 |

|

Die Size |

4-15(Up to 9 Two Die) |

|

Production |

1900-2700 Pcs/Hr |

|

Raw Material |

80 GSM to 450 GSM |

|

Power Source |

220V, 50Hz |

|

Electric Motor |

2HP |

|

Power Consumption |

2-2.5 Unit/Hr |

|

Oil Tank Capacity |

45 Ltrs |

|

Weight |

300kg |

Free Accessories

- Heater Set of Free Dies

- Ptfe Sheet = 1

- Die Connector = 4

- Spanner Set

- Rubber Pad

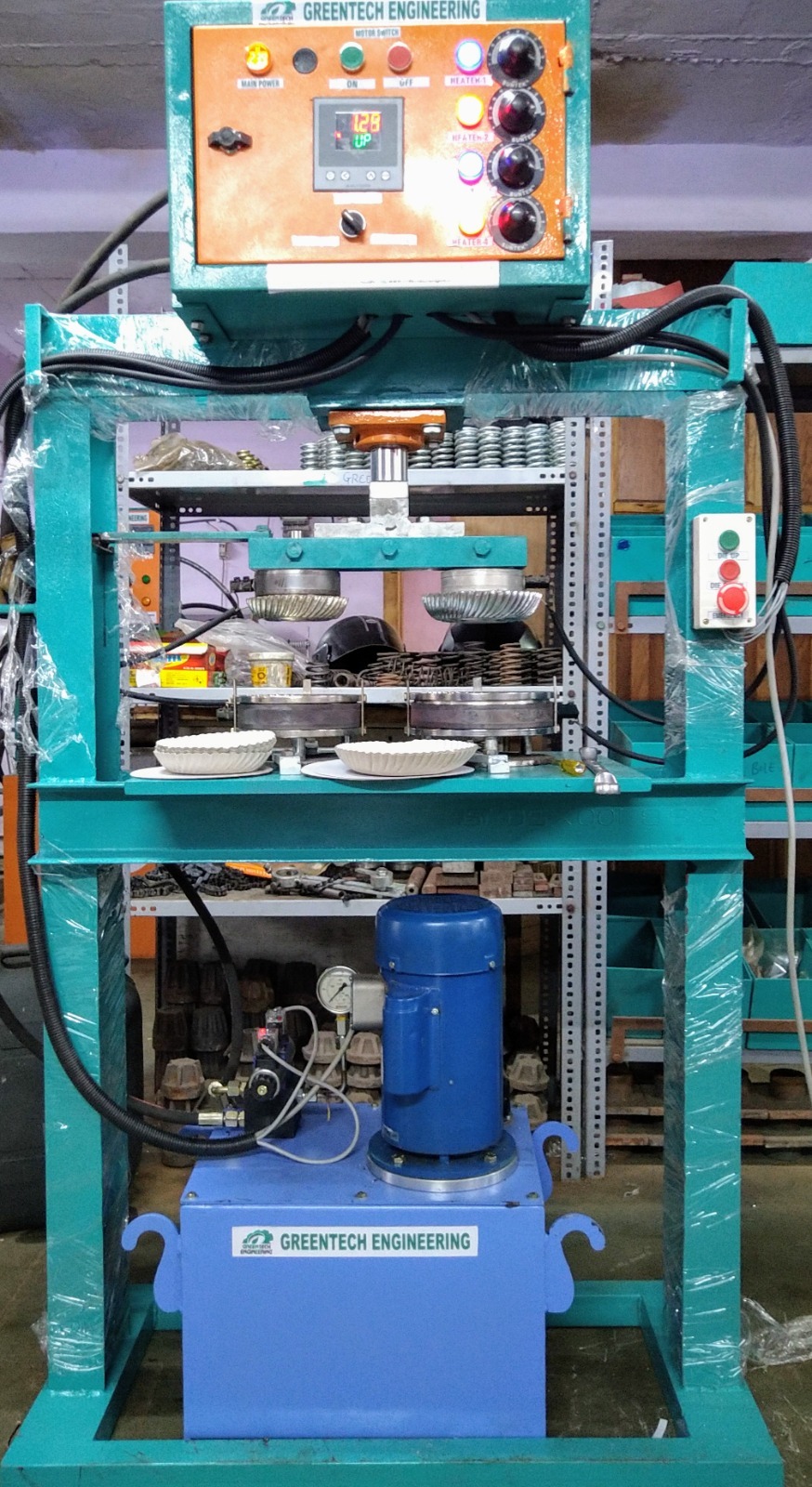

Safe and Sturdy Construction

This plate making machine is engineered with a sturdy, heat-resistant, and corrosion-proof body to withstand regular use and harsh environments. The integrated operator safety guard reduces the risk of injuries, making daily operations safer for all users and offering peace of mind alongside reliable performance.

Simple Operation and Maintenance

The machine incorporates a manual operation system and a user-friendly Human Machine Interface control, making it accessible for operators of various skill levels. Its tabletop design and easy-to-clean surfaces streamline daily maintenance and ensure hygienic production, saving both time and effort for your staff.

Reliable Warranty Coverage

Every unit comes with a one-year warranty on the motor and programmable timer, underscoring our commitment to quality assurance. As an experienced exporter, importer, manufacturer, and supplier in India, we provide dependable after-sales support, ensuring you get the most from your investment.

FAQ's of Plate Making machine:

Q: How does the operator safety guard enhance safety during use?

A: The operator safety guard acts as a protective barrier to shield the user from potential moving parts or accidental contact, significantly minimizing the risk of injuries during manual operation.Q: What steps are involved in the plate making process with this machine?

A: The process begins by preparing the raw material and placing it on the die. Using manual operation, you engage the pressing mechanism. The heat-resistant body allows for continuous use, and finished plates are easily removed and cleaned off the tabletop surface.Q: When should the machine be cleaned for optimal performance?

A: It is recommended to clean the machine after each production session. The easy-to-clean design allows quick removal of residue, maintaining hygiene and extending the machine's lifespan.Q: Where can this plate making machine be installed?

A: Thanks to its compact tabletop design and single-phase power compatibility, the machine can be installed in small workshops, commercial kitchens, or even mobile setups where space and standard electrical supply are available.Q: What benefits does the Human Machine Interface control system provide?

A: The Human Machine Interface simplifies the control of the machine, making it straightforward to operate, even for users with limited technical experience. It reduces setup time and enhances precision through intuitive settings.Q: How does the warranty cover the machine?

A: The warranty covers the motor and programmable timer for one year from the date of purchase. This ensures repair or replacement of these critical parts in case of manufacturing defects, providing added assurance for your investment.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Plate Making Machine' category

We mainly deal in Maharashtra, Gujarat, Madhya Pradesh and Rajasthan.

|

GREENTECH ENGINEERING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |