Paper Plate Machine

120000 INR

Product Details:

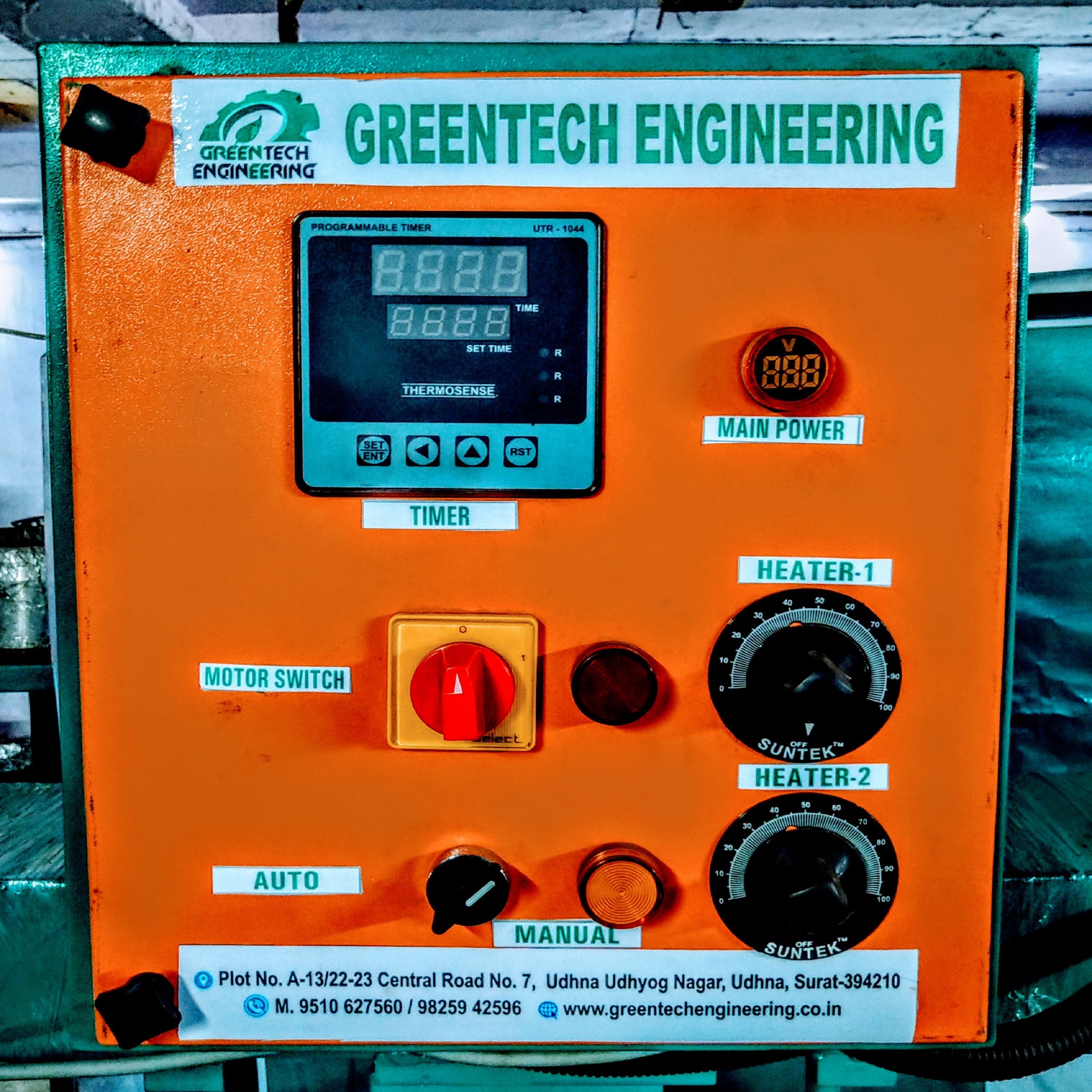

- Control System Human Machine Interface

- Warranty One year of Motor and Programmable Timer

- Click to View more

X

Paper Plate Machine Price And Quantity

- 120000 INR

- 01 Piece

Paper Plate Machine Product Specifications

- Human Machine Interface

- One year of Motor and Programmable Timer

Paper Plate Machine Trade Information

- 50-60 Piece Per Month

- 5-7 Days

- Yes

- All India

Product Description

Technical Specifications

| Model No. | GT-P10 |

| Die Size | 4-15(Up to 9 Two Die) |

| Production | 1900-2700 Pcs/Hr |

| Raw Material | 80 GSM to 450 GSM |

| Power Source | 220V, 50Hz |

| Electric Motor | 2HP |

| Power Consumption | 2-2.5 Unit/Hr |

| Oil Tank Capacity | 45 Ltrs |

| Weight | 300kg |

Free Accessories

- Heater Set of Free Dies

- Ptfe Sheet = 1

- Die Connector = 4

- Spanner Set

- Rubber Pad

Efficient and Safe Paper Plate Production

Experience unmatched productivity with our paper plate machine, featuring an automatic feeding system and quick-change dies for minimal downtime. The enclosed safety guard, heavy-duty steel frame, and intuitive Human Machine Interface ensure both safety and convenience throughout operation. Designed for smooth and high-capacity output, it's a reliable partner for manufacturers looking to scale up paper plate production.

Advanced Features and User-Friendly Operation

Operate with ease using button-start and a simple push-button switch, all managed via an ergonomic Human Machine Interface. The single-phase motor delivers consistent performance, while the aluminum heating plate ensures even and precise plate formation. Switch between dies quickly to accommodate various plate sizes, enhancing flexibility for shifting production demands.

FAQ's of Paper Plate Machine:

Q: How does the automatic feeding system in this paper plate machine work?

A: The automatic feeding system streamlines the production process by continuously supplying raw material to the dies, minimizing manual intervention and significantly increasing the rate of production.Q: What is the benefit of the quick change system for dies?

A: The quick change die system allows operators to swiftly switch between different die sizes or designs, reducing downtime and increasing the versatility of the machine for handling various orders efficiently.Q: When is maintenance recommended for this paper plate machine?

A: Routine maintenance should be performed according to the manufacturer's instructions, typically as outlined in the user manual. This includes regular checks for electrical, mechanical, and heating components to ensure smooth operation and longevity.Q: Where is this machine manufactured and can it be exported?

A: This paper plate machine is manufactured in India and is available for supply both domestically and internationally, catering to the needs of exporters and importers alike.Q: What is the production capacity of the double die system?

A: The double die feature enables the machine to produce two plates simultaneously, effectively doubling output and making it ideal for high-demand environments.Q: How is user safety ensured during the operation of this paper plate machine?

A: User safety is prioritized through the use of an enclosed safety guard cover, which helps to prevent accidental contact with moving or heated parts during operation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Plate Making Machine' category

We mainly deal in Maharashtra, Gujarat, Madhya Pradesh and Rajasthan.

|

GREENTECH ENGINEERING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |