Paper Dish Machine

115000 INR/Piece

Product Details:

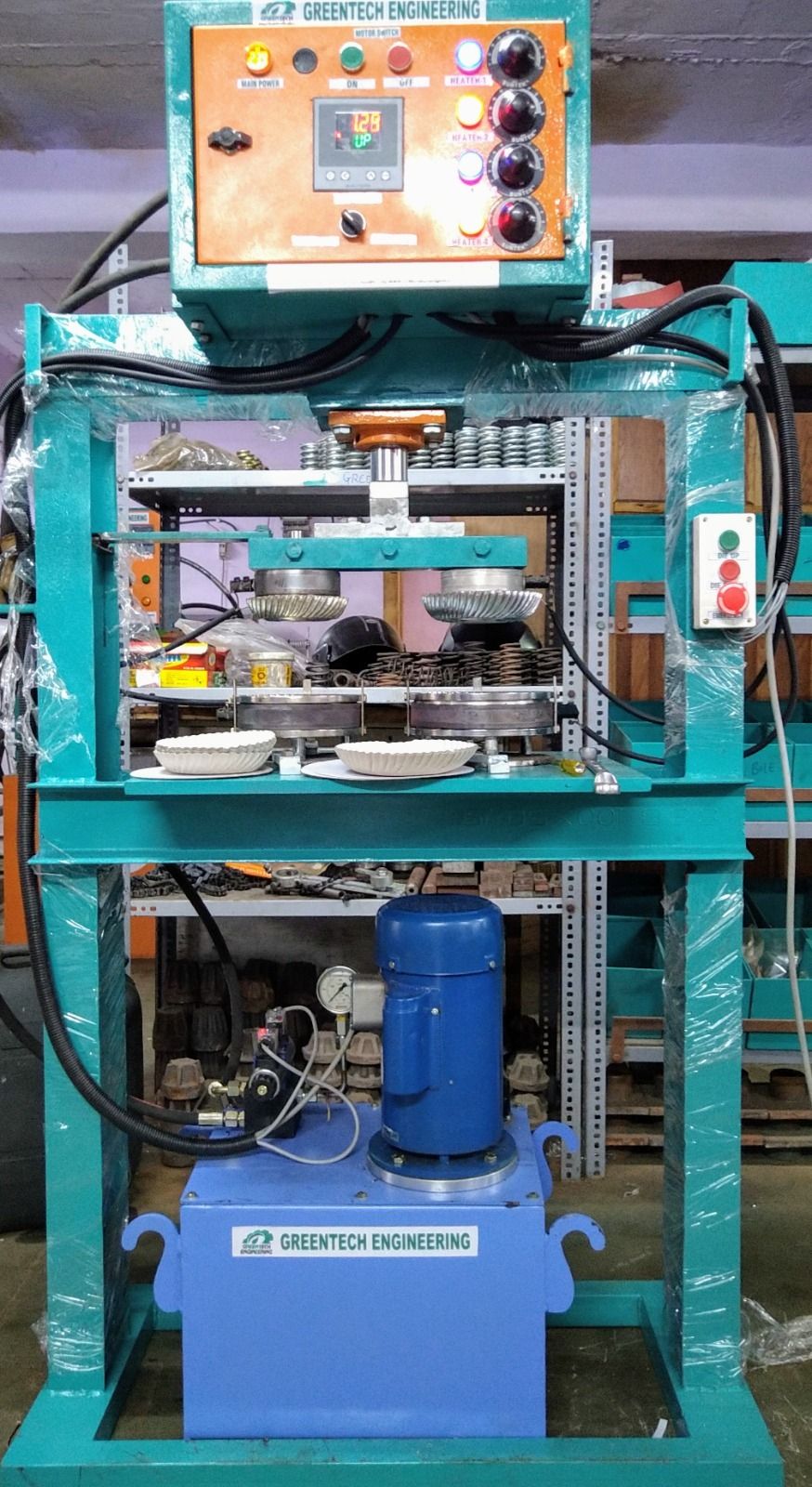

- Grade Semi-Automatic

- Capacity 2000-2700 pc/hr Pcs/min

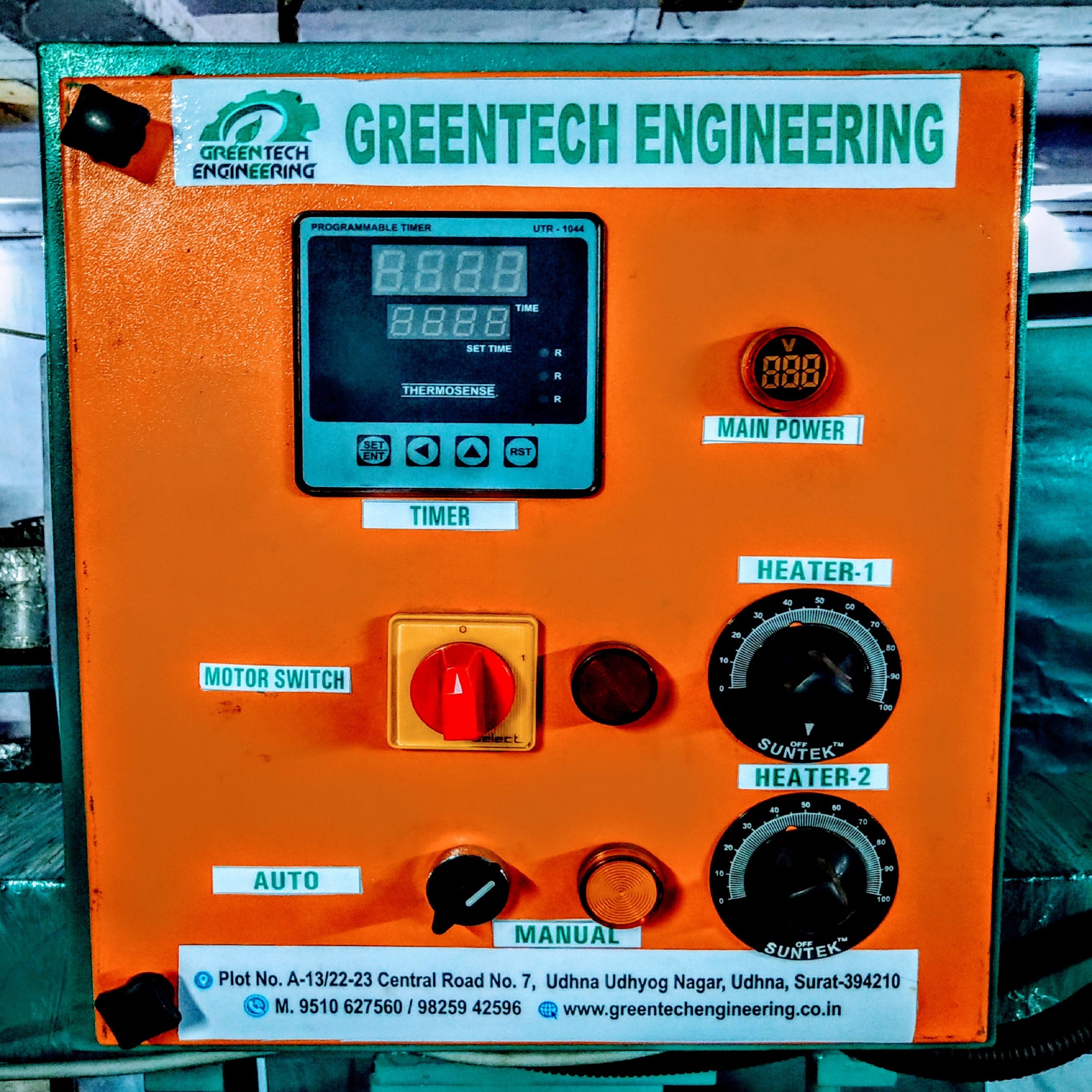

- Control System Human Machine Interface

- Voltage 220v Volt (v)

- Weight (kg) 300 kg Kilograms (kg)

- Dimension (L*W*H) 36(l)" 20(W)" 68(H)" Inch (in)

- Warranty One year of Motor and Programmable Timer

- Click to View more

X

Paper Dish Machine Price And Quantity

- 01 Piece

- 115000 INR/Piece

Paper Dish Machine Product Specifications

- 220v Volt (v)

- 2000-2700 pc/hr Pcs/min

- Human Machine Interface

- 36(l)" 20(W)" 68(H)" Inch (in)

- Semi-Automatic

- One year of Motor and Programmable Timer

- 300 kg Kilograms (kg)

Paper Dish Machine Trade Information

- 50-60 Piece Per Month

- 5-7 Days

- Yes

- Australia, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia, North America

- All India

- ISO Certified

Product Description

Technical Specifications

| Model No. | GT-P10 |

| Die Size | 4-15(Up to 9 Two Die) |

| Production | 1900-2700 Pcs/Hr |

| Raw Material | 80 GSM to 450 GSM |

| Power Source | 220V, 50Hz |

| Electric Motor | 2HP |

| Power Consumption | 2-2.5 Unit/Hr |

| Oil Tank Capacity | 45 Ltrs |

| Weight | 300kg |

Free Accessories

- Heater Set of Free Dies

- Ptfe Sheet = 1

- Die Connector = 4

- Spanner Set

- Rubber Pad

Efficient and User-Friendly Operation

Leverage seamless interaction with this paper dish machine's Human Machine Interface. The semi-automatic grade ensures a balance between automation and hands-on operation, providing flexibility without compromising productivity. The system is engineered to meet varied business requirements, supporting quick setup and intuitive control for operators.

High Production Capacity for Growing Demands

Capable of producing between 2000 and 2700 dishes per hour, this machine is perfect for establishments needing consistent, large-scale output. Its durable build and reliable performance empower businesses such as catering companies and packaging suppliers to meet increasing market demands efficiently.

Reliable Build and Warranty Assurance

Designed with a sturdy structure, the machine measures 36 by 20 by 68 inches and weighs 300 kilograms, ensuring stability during operation. Buyers benefit from a one-year warranty on the motor and programmable timer, underscoring the manufacturer's commitment to quality and customer satisfaction.

FAQ's of Paper Dish Machine:

Q: How do I operate the Semi-Automatic Paper Dish Machine?

A: The machine uses a Human Machine Interface, allowing operators to easily monitor and control the production process. Basic setup involves connecting to a 220v power source and following on-screen prompts for operation, ensuring straightforward and safe use.Q: What types of paper dishes can this machine manufacture?

A: This machine is suitable for producing various sizes and shapes of disposable paper dishes, commonly used in food service, catering, and packaging industries. Its adjustable settings allow for customization based on your specific requirements.Q: When is the ideal time for maintenance on this machine?

A: Routine maintenance should be performed every few months, depending on usage intensity. Regular checks of the motor, timer, and interface help maintain optimal performance and ensure that the one-year warranty covers potential issues.Q: Where can I purchase this Semi-Automatic Paper Dish Machine in India?

A: The machine is available through exporters, importers, manufacturers, and suppliers across India. Interested buyers can connect with authorized dealers or directly approach the manufacturing companies for purchase and after-sales support.Q: What is the process for producing paper dishes with this machine?

A: The process involves loading paper material into the machine, configuring settings via the interface, and starting the cycle. The semi-automatic system handles pressing and shaping, producing 2000-2700 pieces per hour efficiently.Q: How does using this machine benefit my business?

A: Employing this machine streamlines production, reduces labor costs, and boosts output, enabling businesses to meet market demands swiftly. The high-speed capacity and ease of use help maximize operational efficiency and profitability.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Paper Plate Making Machine' category

We mainly deal in Maharashtra, Gujarat, Madhya Pradesh and Rajasthan.

|

GREENTECH ENGINEERING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |