Single Die Paper Plate Making Machine

100000 INR/Piece

Product Details:

- Warranty One year of Motor and Blower

- Click to View more

X

Single Die Paper Plate Making Machine Price And Quantity

- 100000 INR/Piece

- 01 Piece

Single Die Paper Plate Making Machine Product Specifications

- One year of Motor and Blower

Single Die Paper Plate Making Machine Trade Information

- 100 Piece Per Month

- 5-7 Days

- Yes

- Western Europe, Asia, North America, Eastern Europe, Central America, Middle East, South America, Australia, Africa

- All India

Product Description

Technical Specifications

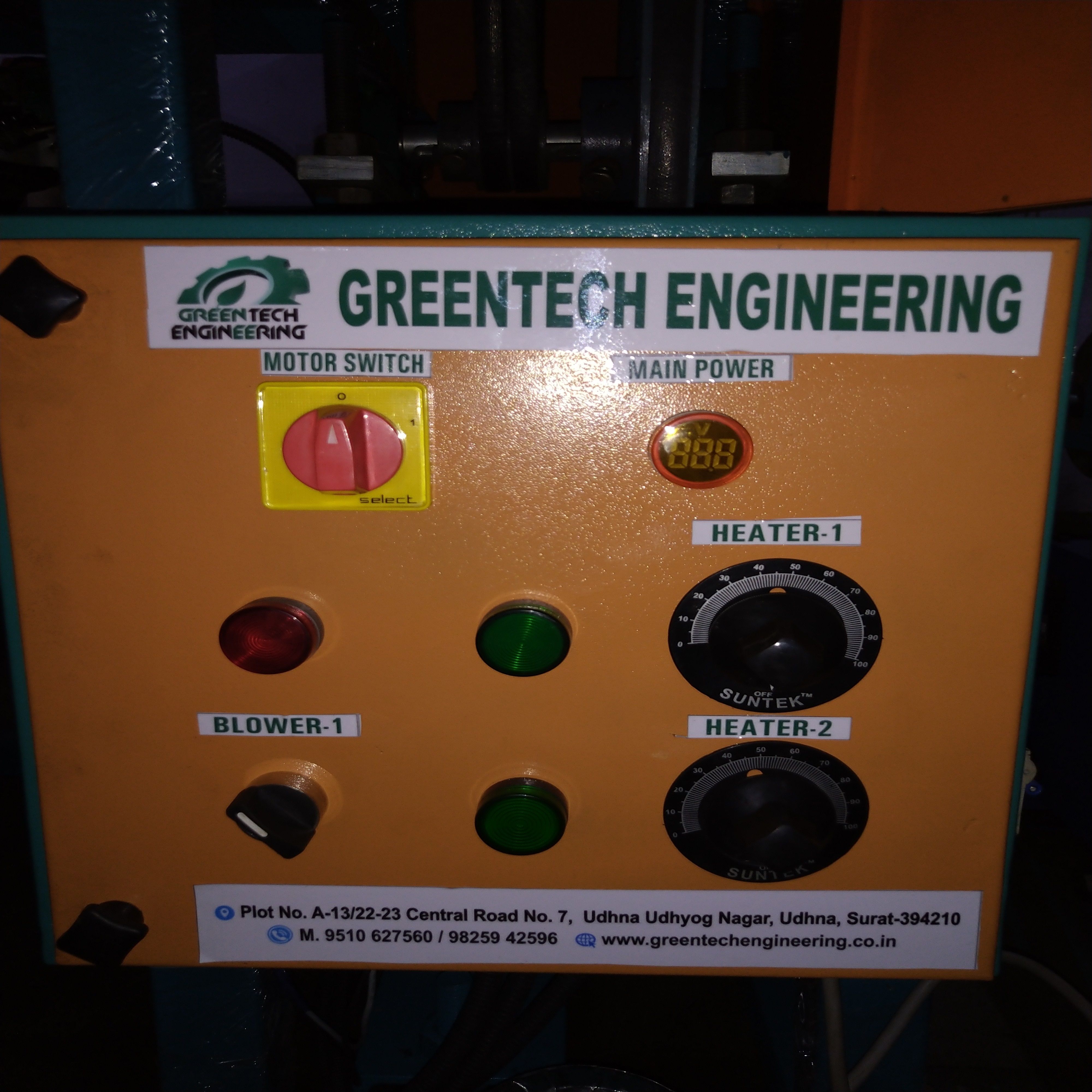

| Model No. | GT-D01 |

| Die Size | 4"-14" |

| Production | 900-1400 Pcs/Hr |

| Raw Material | 80 GSM to 180 GSM |

| Power Source | 220V, 50Hz |

| Electric Motor | 1HP |

| Power Consumption | 1-1.5 Unit/Hr |

| Dimension | 32"(L) x 26"(W) x 68"(H) |

| Weight | 250kg |

Free Accessories

| Heater Set of Free Dies |

| Pressure Spring = 2 |

| Long Spring = 1 |

| Die Connector = 4 |

| Spanner Set |

| Rubber Pad |

Robust and Reliable Construction

This machine boasts a rigid, heavy-duty frame built from mild steel, ensuring long-lasting durability and reliable performance. Its compact construction makes it suitable for workshops or spaces with limited area, allowing businesses to maximize production without sacrificing valuable floor space.

Simplified Operation and Efficient Output

The semi-automatic operation, featuring a single die, offers straightforward production of paper plates. Manual foot pedal control provides precision, while the attached blower enhances efficiency. The electric motor ensures smooth, consistent power, supporting high productivity with minimal user effort.

Low Maintenance, High Value

Designed for low maintenance, the Single Die Paper Plate Making Machine saves time and effort. Easy-to-access components make routine care simple. The product comes with a one-year warranty on the motor and blower, contributing peace of mind for owners and operators.

FAQ's of Single Die Paper Plate Making Machine:

Q: How is the Single Die Paper Plate Making Machine operated?

A: The machine is semi-automatic and uses a single die for operation. It is controlled manually with a foot pedal, which allows the user to operate the die with precision. The power source is an electric motor, and an attached blower is included to help with plate formation.Q: What types of plates can this machine produce?

A: This machine is specifically designed for manufacturing paper plates. The single die setup ensures uniformity, making it suitable for standard-sized disposable plate production.Q: When is maintenance required for the machine?

A: Routine maintenance is straightforward and can be performed at regular intervals, such as cleaning and lubricating moving parts. The design allows easy access to components, minimizing downtime. The motor and blower are covered by a one-year warranty for additional assurance.Q: Where can this machine be installed?

A: Due to its compact and sturdy design, the machine can be installed in small workshops, home-based units, or medium-scale paper product factories with space limitations.Q: What is the process for making plates with this machine?

A: To produce paper plates, the operator places the raw material onto the die, then uses the foot pedal to press and shape the plate. The electric motor and blower aid in forming and removing plates efficiently, maximizing output.Q: What are the benefits of using this machine for paper plate production?

A: Key benefits include robust construction, space-saving design, easy maintenance, and reliable operation. The manual control ensures accuracy, while the electric motor and blower improve production efficiency. The machine's one-year warranty on critical parts further enhances its value for businesses.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Paper Plate Making Machine' category

We mainly deal in Maharashtra, Gujarat, Madhya Pradesh and Rajasthan.

|

GREENTECH ENGINEERING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |