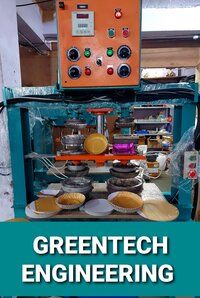

Automatic Four Die Paper Plate Making Machine

140000 INR/Piece

Product Details:

- Warranty One year of Motor and Programmable Timer

- Click to View more

X

Automatic Four Die Paper Plate Making Machine Price And Quantity

- 140000 INR/Piece

- 01 Piece

Automatic Four Die Paper Plate Making Machine Product Specifications

- One year of Motor and Programmable Timer

Automatic Four Die Paper Plate Making Machine Trade Information

- 5 Piece Per Month

- 5-7 Days

- Yes

- All India

Product Description

Technical Specifications

| Model No. | GT-P17 |

| Die Size | 4"ï-15" (Up to 9"Four Die) |

| Production | 3800-4700 Pcs/Hr |

| Raw Material | 80 GSM to 450 GSM |

| Power Source | 220V, 50Hz |

| Electric Motor | 2HP |

| Power Consumption | 2.5-3 Unit/Hr |

| Oil Tank Capacity | 45 Ltrs |

| Weight | 350kg |

Free Accessories

| Heater Set of Free Dies |

| Teflon Sheet = 1 |

| Die Connector = 8 |

| Spanner Set |

| Rubber Pad |

Fully Automated, High-Yield Production

This machine streamlines the plate-making process with its fully automatic hydraulic press system, allowing operators to produce a wide variety of paper plate sizes at an impressive rate. Four dies work simultaneously to maximize efficiency and satisfy high-volume demand for businesses.

Durable Structure for Safety and Longevity

Built with a heavy-duty frame, the machine ensures safe operation and extended durability. Its robust design reduces downtime due to mechanical faults, contributing to a productive and secure working environment for continuous usage.

Versatile and Low-Maintenance Solution

Compatible with multiple GSM paper types, the machine excels in versatility. Its simplified maintenance requirements minimize operational costs, ensuring that even small and large-scale businesses find it cost-effective without sacrificing quality or reliability.

FAQ's of Automatic Four Die Paper Plate Making Machine:

Q: How does the Automatic Four Die Paper Plate Making Machine operate?

A: The machine uses a fully automatic hydraulic press to streamline plate production. Four dies allow simultaneous fabrication of plates, enhancing productivity and ensuring consistent quality across various sizes.Q: What paper types and sizes can this machine handle?

A: It is compatible with multiple GSM paper variants and is capable of producing both small and large-sized paper plates, thanks to its interchangeable die system.Q: When is maintenance required for this machine?

A: With its low-maintenance design, the machine typically requires routine inspections and servicing at infrequent intervals, minimizing downtime and cost.Q: Where can this machine be installed for best performance?

A: Ideal for manufacturing units, commercial facilities, and small to large-scale enterprises, it should be installed in a spacious, stable area, ensuring easy access for operation and maintenance.Q: What is the process for changing plate sizes?

A: To switch plate sizes, simply change the dies according to the desired specification. The machine is engineered for easy and swift die replacement, eliminating production delays.Q: How does using this machine benefit exporters and suppliers?

A: Its high yield, reliable performance, and full automation system help exporters and suppliers meet bulk orders efficiently, thus supporting scalable growth in competitive markets.Q: What warranty and support are provided?

A: The machine comes with a one-year warranty covering both the motor and programmable timer, ensuring peace of mind for buyers regarding key components.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Automatic Paper Plate Making Machine' category

We mainly deal in Maharashtra, Gujarat, Madhya Pradesh and Rajasthan.

|

GREENTECH ENGINEERING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |