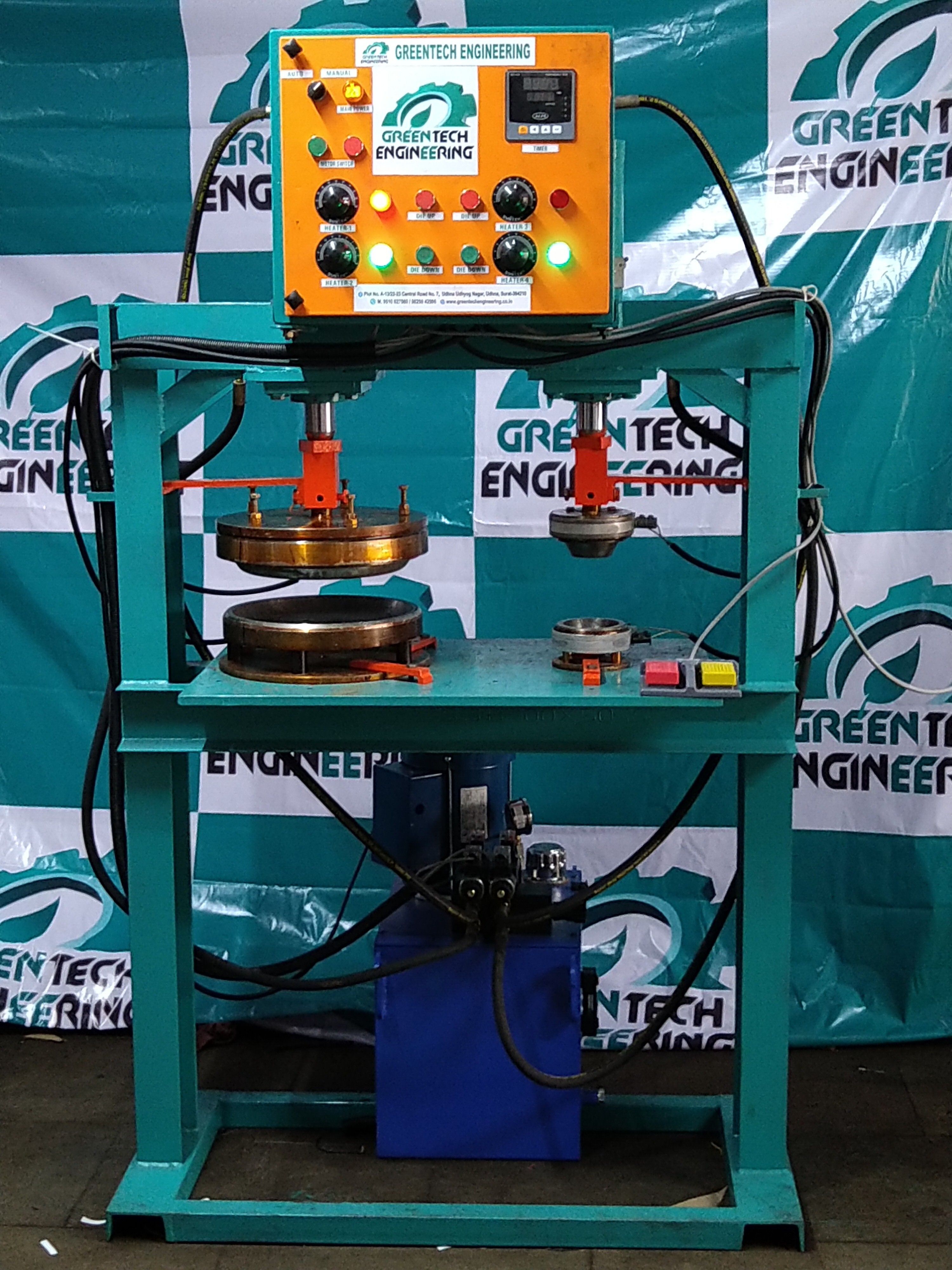

Fully Automatic Paper Plate Making Machine

180000.0 INR/Unit

Product Details:

- Type Paper Cutting Machine

- Material Silver, White, Color

- Capacity 6 Kg/hr

- Computerized Yes

- Control System PLC Control

- Cutting Speed 3500 mm/m

- Cutting Size 80 - 350

- Click to View more

X

Fully Automatic Paper Plate Making Machine Price And Quantity

- 180000.0 INR/Unit

- 1 Unit

Fully Automatic Paper Plate Making Machine Product Specifications

- 250 Kilograms (kg)

- green

- Yes

- PLC Control

- Silver, White, Color

- 80 - 350

- 1 year

- 220 Volt (v)

- Paper Cutting Machine

- 80 - 350 Inch

- 6 Kg/hr

- 220 Volt (v)

- 3500 mm/m

Fully Automatic Paper Plate Making Machine Trade Information

- 1 Unit Per Day

- 1 Week

- No

- All India

- ISO

Product Description

Technical Specifications

|

Model No. |

GT-P09 |

|

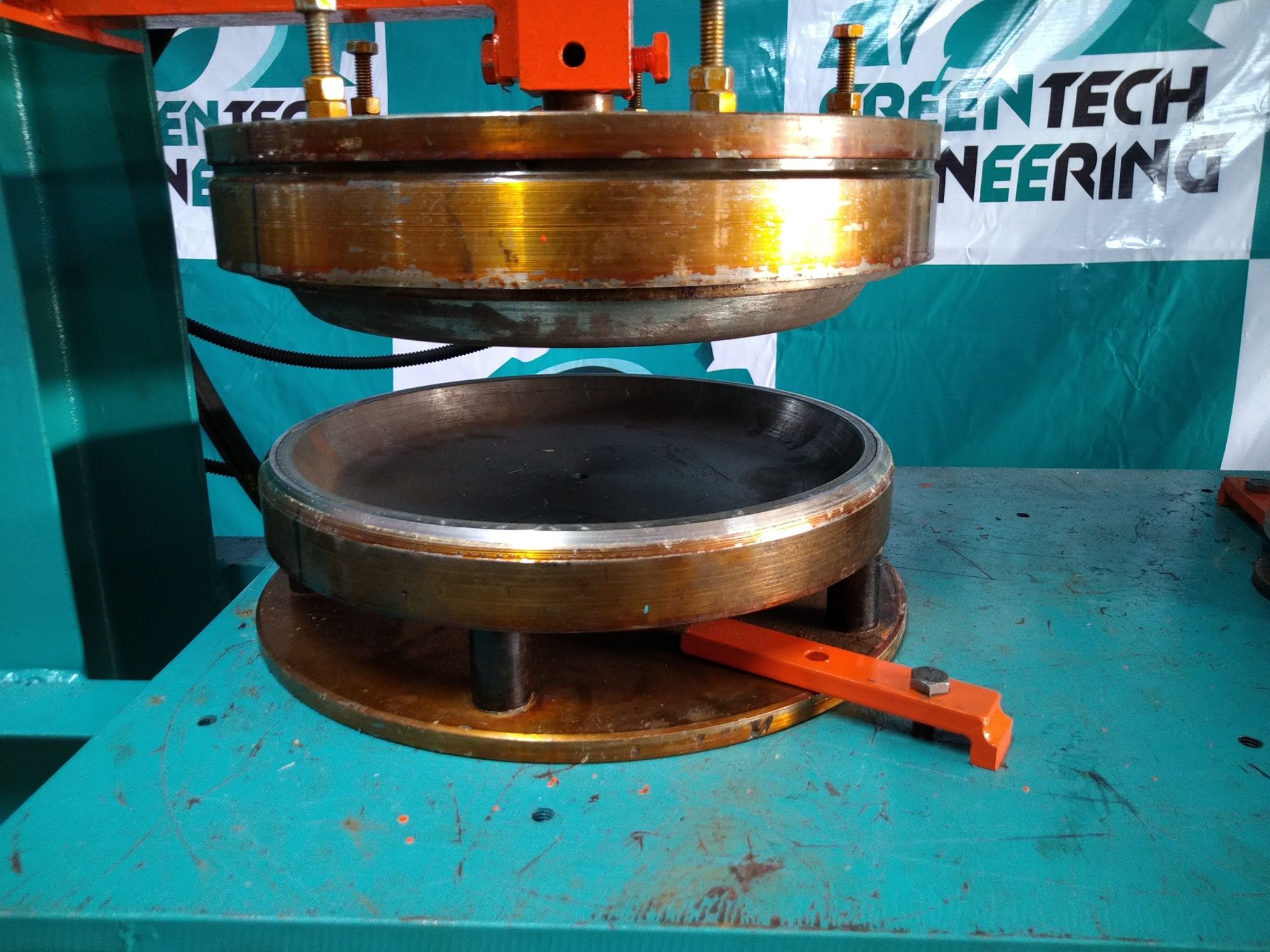

Die Size |

4-18 |

|

Production |

2700-3000 Pcs/Hr |

|

Raw Material |

80 GSM to 450 GSM |

|

Power Source |

220V, 50Hz |

|

Electric Motor |

2HP |

|

Power Consumption |

2.5-3 Unit/Hr |

|

Oil Tank Capacity |

45 Ltrs |

|

Weight |

350kg |

Free Accessories

- Heater Set of Free Dies

- Ptfe Sheet = 1

- Die Connector = 8

- Spanner Set

- Rubber Pad

Advanced PLC Control System

The integration of a PLC control system ensures consistent precision and user-friendly operation. This advanced automation allows manufacturers to streamline plate production, reduce manual error, and easily monitor key metrics throughout the process. Operators benefit from intuitive controls and real-time diagnostics for optimal machine performance.

High-Efficiency Cutting and Production

Designed with a powerful cutting mechanism, the machine achieves speeds up to 3,500 mm/m while maintaining accuracy in thickness from 80 to 350 inches. Its 6 kg/hr capacity enables businesses to meet high-volume demands efficiently, maximizing productivity across daily operations.

Flexible Material and Plate Sizes

Accommodating silver, white, and colored paper materials, this machine offers versatility for diverse product requirements. Users can customize plate sizes and thicknesses to suit different markets, making it ideal for both export and domestic supply chains.

FAQ's of Fully Automatic Paper Plate Making Machine:

Q: How does the fully automatic paper plate making machine operate with PLC control?

A: The machine utilizes a PLC (Programmable Logic Controller) system that automates the production process, enabling precise control over cutting size, speed, and plate thickness. Operators simply input settings using the computerized interface to start and monitor the manufacturing cycle.Q: What types of paper materials can be used with this machine?

A: This machine is compatible with silver, white, and colored paper materials, offering flexibility for creating a variety of paper plate designs to meet specific client or market needs.Q: When should the warranty be claimed and what does it cover?

A: The included one-year warranty covers manufacturing defects and issues related to machine performance. If operational problems arise within the warranty period, contact your supplier or manufacturer for prompt support and necessary repairs.Q: Where can this paper plate making machine be installed and used?

A: It is designed for factories, workshops, or business units in India involved in paper plate production-especially suitable for manufacturers, exporters, importers, or suppliers requiring reliable, computerized equipment.Q: What is the advantage of a computerized, automatically controlled production process?

A: Computerized control with automatic PLC operation minimizes manual labor, reduces production errors, and ensures consistent quality output. This enhances efficiency, reliability, and scalability for business growth.Q: How is the paper cutting process managed to achieve different plate sizes and thicknesses?

A: Operators can set the desired cutting size (80-350) and thickness (80-350 inches) through the computerized system. The PLC precisely executes these specifications, guaranteeing uniform and accurate plate outputs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Automatic Paper Plate Making Machine' category

We mainly deal in Maharashtra, Gujarat, Madhya Pradesh and Rajasthan.

|

GREENTECH ENGINEERING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |