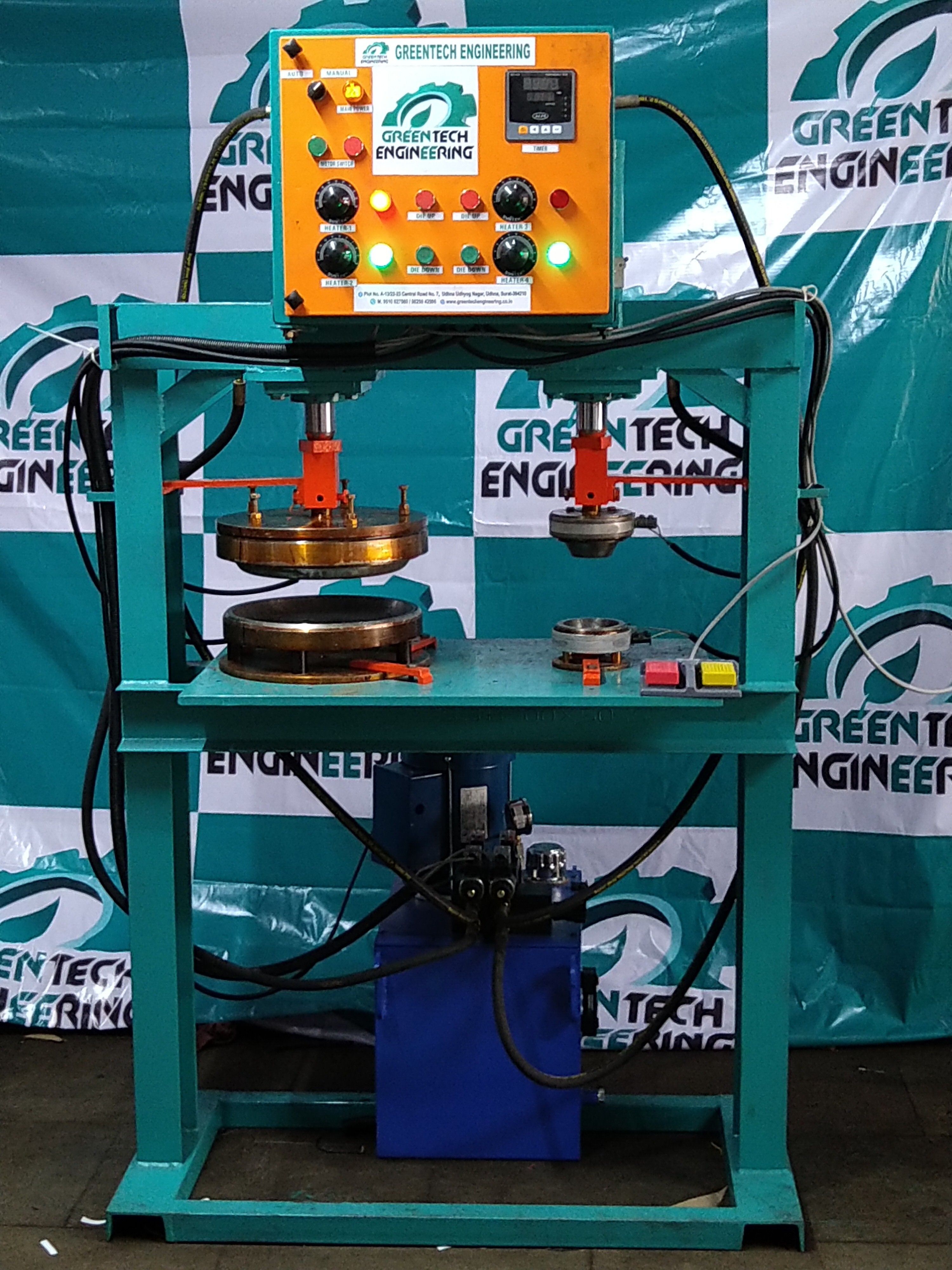

Hydraulic Double Cylinder Paper Plate Making Machine

165000 INR/Piece

Product Details:

- Warranty One year of Motor and Programmable Timer

- Click to View more

X

Hydraulic Double Cylinder Paper Plate Making Machine Price And Quantity

- 01 Piece

- 165000 INR/Piece

Hydraulic Double Cylinder Paper Plate Making Machine Product Specifications

- One year of Motor and Programmable Timer

Hydraulic Double Cylinder Paper Plate Making Machine Trade Information

- Western Union, Paypal, Cheque

- 5-7 Days

- Yes

- All India

Product Description

Technical Specifications

| Model No. | GT-P09 |

| Die Size | 4"-18" |

| Production | 2700-3000 Pcs/Hr |

| Raw Material | 80 GSM to 450 GSM |

| Power Source | 220V, 50Hz |

| Electric Motor | 2HP |

| Power Consumption | 2.5-3 Unit/Hr |

| Oil Tank Capacity | 45 Ltrs |

| Weight | 350kg |

Free Accessories

| Heater Set of Free Dies |

| Teflon Sheet = 1 |

| Die Connector = 8 |

| Spanner Set |

| Rubber Pad |

Advanced Double Cylinder Technology

With its dual hydraulic cylinders, this machine offers smooth operation and greater production efficiency. The twin-cylinder design ensures synchronized movement and maintains consistent pressure, resulting in neatly formed plates and reduced wear over time. The automatic system minimizes manual intervention, allowing operators to focus on productivity.

Heavy-Duty Construction & Safety

Fabricated from high-grade steel, the frame provides unwavering stability during continuous operation. Integrated safety switches keep the working environment secure and prevent accidental starts. The powder-coated finish resists corrosion, ensuring a longer machine lifespan even in demanding manufacturing environments.

User Interactions & Warranty

The machine operates automatically with just a few user inputs, making it suitable for both experienced operators and new users. Its electric power source and programmable timer allow easy setup for different plate sizes and quantities. The included one-year warranty on the motor and timer delivers peace of mind and reliable after-sales support across India.

FAQ's of Hydraulic Double Cylinder Paper Plate Making Machine:

Q: How does the Hydraulic Double Cylinder Paper Plate Making Machine work?

A: This fully automatic machine utilizes two high-pressure hydraulic cylinders to press and form paper plates. Once the paper is loaded, the machine's electric system and programmable timer regulate each cycle, ensuring efficient, uniform plate production with minimal operator intervention.Q: What are the benefits of the heavy-duty steel frame and powder-coated finish?

A: The heavy-duty steel frame offers durability and stability, essential for high-speed, long-term operation. The powder-coated finish protects the machine from corrosion and environmental wear, extending its service life in industrial applications.Q: When should the machine's safety features be checked?

A: It is advisable to inspect the integrated safety switches before each production run or during routine maintenance. Regular checks help ensure that the machine operates safely and prevent unintended startups or potential mishaps.Q: Where can this paper plate making machine be used?

A: This machine is ideal for use in manufacturing facilities, small-scale and large-scale production units, and can serve both domestic and export operations. It is well-suited for exporters, importers, manufacturers, and suppliers across India seeking high-capacity solutions.Q: What is the production capacity and applicable plate size for this machine?

A: The machine is capable of producing 2000 to 2500 paper plates per hour and can accommodate plate sizes up to 14 inches, making it suitable for diverse requirements and high-volume output.Q: How is the machine powered and what materials can it process?

A: The machine operates on electricity and is designed specifically for manufacturing plates from paper material. The hydraulic system delivers high pressure for efficient and precise plate formation.Q: What warranty is provided with the machine?

A: Customers receive a one-year warranty covering both the motor and the programmable timer. This warranty is supported by reliable after-sales service for complete peace of mind.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Hydraulic Paper Plate Making Machine' category

We mainly deal in Maharashtra, Gujarat, Madhya Pradesh and Rajasthan.

|

GREENTECH ENGINEERING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |