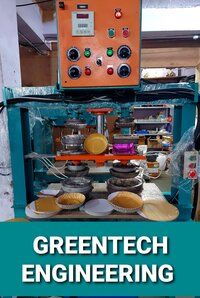

Four Die Hydraulic Paper Plate Making Machine

140000 INR

Product Details:

- Type Other

- Control System Human Machine Interface

- Warranty One year of Motor and Programmable Timer

- Click to View more

X

Four Die Hydraulic Paper Plate Making Machine Price And Quantity

- 140000 INR

- 01 Piece

Four Die Hydraulic Paper Plate Making Machine Product Specifications

- Other

- Human Machine Interface

- One year of Motor and Programmable Timer

Four Die Hydraulic Paper Plate Making Machine Trade Information

- 40 - 50 Piece Per Month

- 5-7 Days

- Yes

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Africa, Asia

- All India

Product Description

Technical Specifications

| Model No. | GT-P17 |

| Die Size | 4"ï-15" (Up to 9"Four Die) |

| Production | 3800-4700 Pcs/Hr |

| Raw Material | 80 GSM to 450 GSM |

| Power Source | 220V, 50Hz |

| Electric Motor | 2HP |

| Power Consumption | 2.5-3 Unit/Hr |

| Oil Tank Capacity | 45 Ltrs |

| Weight | 350kg |

Free Accessories

| Heater Set of Free Dies |

| Teflon Sheet = 1 |

| Die Connector = 8 |

| Spanner Set |

| Rubber Pad |

High Output with Advanced Hydraulic Technology

This machine utilizes four dies in combination with a hydraulic drive system to deliver high production rates, making it ideal for businesses requiring volume output. The semi-automatic control ensures ease of operation, while the electric motor provides consistent power for continuous paper plate manufacturing.

Durable Construction and User-Focused Design

Built with heavy duty steel, this floor-standing unit promises longevity and stability during operation. Safety is addressed through robust guards and a user-friendly human-machine interface, enhancing both operator confidence and efficiency. The blue exterior offers visibility and a modern aesthetic.

FAQ's of Four Die Hydraulic Paper Plate Making Machine:

Q: How does the Four Die Hydraulic Paper Plate Making Machine operate?

A: The machine works using hydraulic power driven by an electric motor. It features four dies that simultaneously shape paper into plates. The operator uses the semi-automatic control system, accessible via a human-machine interface, to manage production with efficiency and safety.Q: What types of paper materials are suitable for this machine?

A: This machine is specifically designed to process various grades of paper, making it highly versatile for producing different sizes and types of paper plates, depending on your application needs.Q: When should maintenance be performed on the machine?

A: Routine maintenance, such as checking hydraulic fluid levels, inspecting the dies, and ensuring the electric motor runs smoothly, should be carried out regularly-ideally, monthly. Immediate attention is needed if performance issues or unusual noises arise during operation.Q: Where is the machine typically installed?

A: The machine is intended for indoor use and should be mounted on a stable floor. It is commonly used in production facilities, paper product workshops, and manufacturing plants across India.Q: What is the paper plate manufacturing process with this equipment?

A: The operator loads suitable paper sheets onto the machine. The hydraulic mechanism then engages the dies, pressing the paper into plate shapes. Finished plates are collected as the process cycles automatically using the semi-automatic control system.Q: How can businesses benefit from using this paper plate machine?

A: Companies enjoy high productivity due to the four-die design and hydraulic efficiency. The semi-automatic operation speeds up plate formation while reducing manual labor, providing a cost-effective and consistent output. The inclusion of safety features and user-oriented controls also support reliable operation.Q: What warranty is provided with the machine?

A: The Four Die Hydraulic Paper Plate Making Machine comes with a one-year warranty covering both the electric motor and the programmable timer, offering added assurance to customers regarding key operational components.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Hydraulic Paper Plate Making Machine' category

We mainly deal in Maharashtra, Gujarat, Madhya Pradesh and Rajasthan.

|

GREENTECH ENGINEERING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |