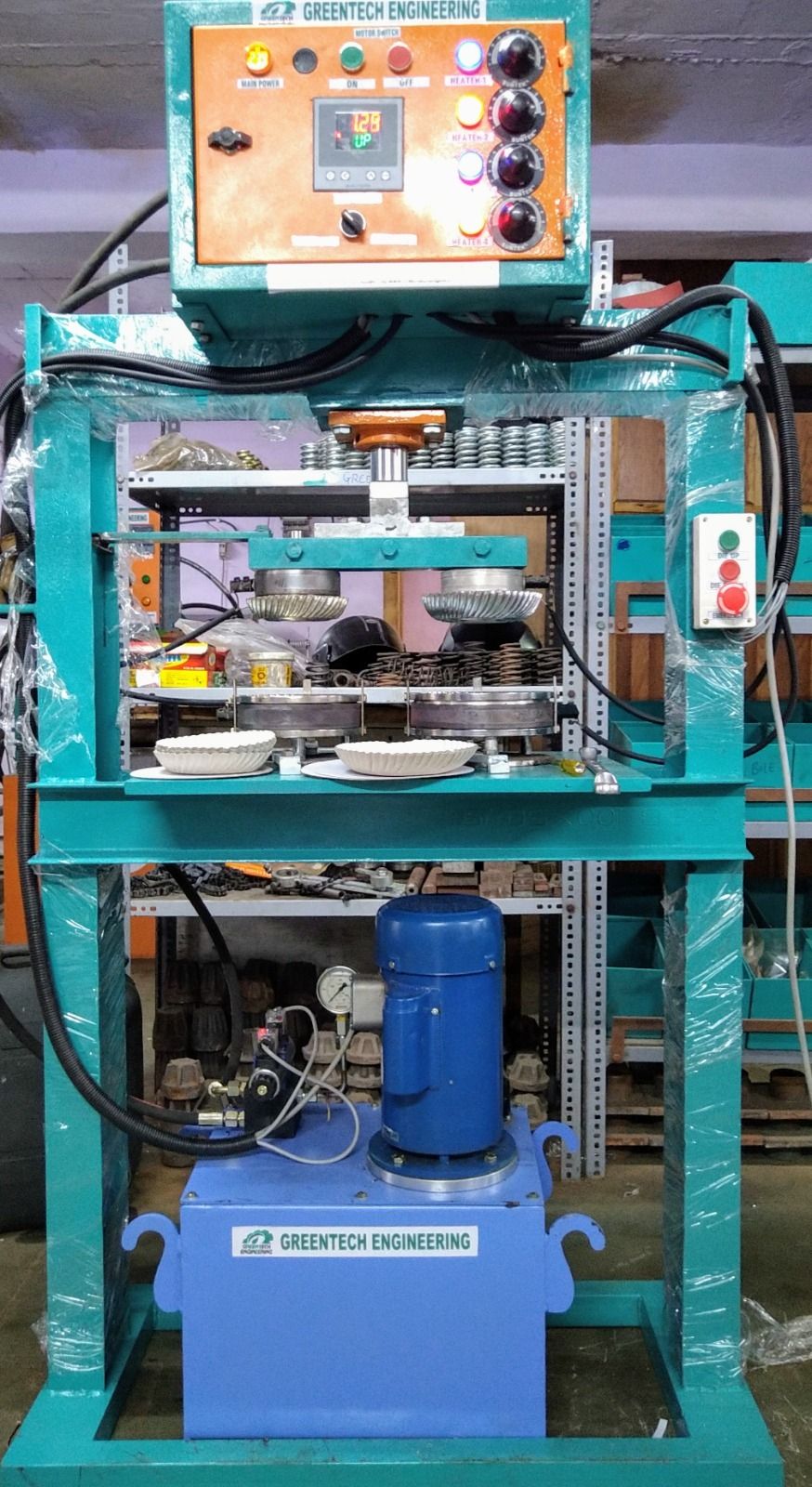

Double Die Paper Dish Making Machine

120000 INR/Piece

Product Details:

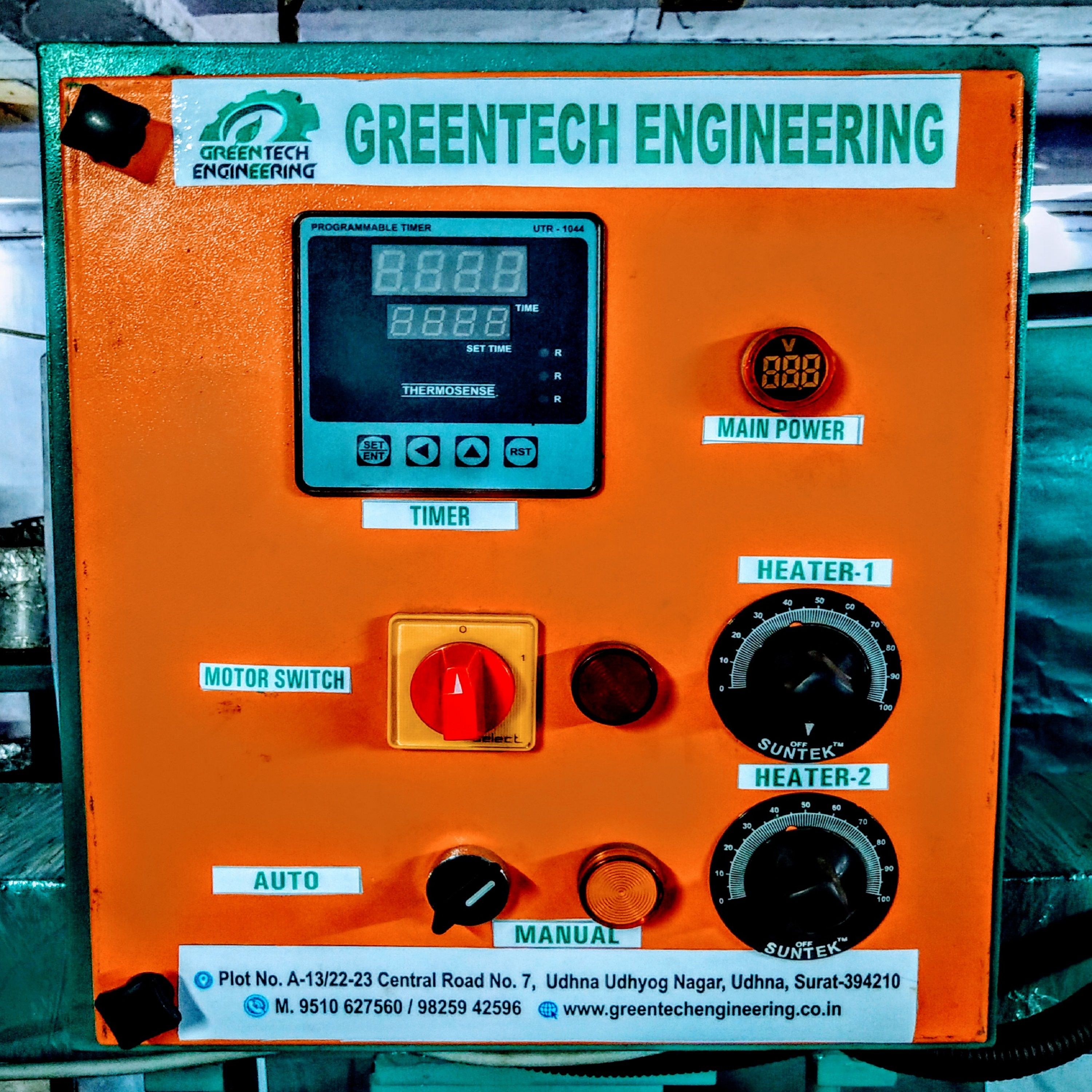

- Warranty One year of Motor and Programmable Timer

- Click to View more

X

Double Die Paper Dish Making Machine Price And Quantity

- 01 Piece

- 120000 INR/Piece

Double Die Paper Dish Making Machine Product Specifications

- One year of Motor and Programmable Timer

Double Die Paper Dish Making Machine Trade Information

- Cheque, Western Union, Paypal

- 100 Piece Per Month

- 5-7 Days

- Yes

- All India

Product Description

Technical Specifications

| Model No. | GT-P10 |

| Die Size | 4"-15"(Up to 9" Two Die) |

| Production | 1900-2700 Pcs/Hr |

| Raw Material | 80 GSM to 450 GSM |

| Power Source | 220V, 50Hz |

| Electric Motor | 2HP |

| Power Consumption | 2-2.5 Unit/Hr |

| Oil Tank Capacity | 45 Ltrs |

| Weight | 300kg |

Free Accessories

| Heater Set of Free Dies |

| Teflon Sheet = 1 |

| Die Connector = 4 |

| Spanner Set |

| Rubber Pad |

Robust Construction and Versatile Operation

Built with a heavy-duty steel frame, this double die paper dish making machine offers substantial durability and stability. It features both manual and automatic sheet feeding options, providing flexibility based on production requirements.

Superior Output with User-friendly Mobility

Delivering high-volume production output, the machine allows users to efficiently manufacture paper dishes. Fitted castor wheels make it easy to maneuver the unit within your workspace, ensuring optimal usability for both small and large facilities.

FAQ's of Double Die Paper Dish Making Machine:

Q: How does the double die system improve production efficiency in this paper dish making machine?

A: The double die configuration enables simultaneous production of two paper dishes, significantly increasing output and reducing manufacturing time compared to single die models.Q: What are the benefits of the heavy-duty steel frame body type?

A: The heavy-duty steel frame provides enhanced durability and stability, which supports prolonged use and resists wear and tear associated with high-volume operations.Q: When should I use manual versus automatic sheet feeding?

A: Manual feeding is suitable for small-batch runs or specific customization, while automatic feeding is recommended for continuous, large-scale production to maximize efficiency.Q: Where is this double die paper dish making machine typically used?

A: This machine is widely used in manufacturing units, export facilities, and supply centers across India that require reliable and high-volume paper dish production.Q: What is the process of operating the semi-automatic machine?

A: The operator loads paper sheets either manually or using the automatic feeder, initiates the production cycle through the control panel, and collects finished dishes for packaging or distribution.Q: How does the low noise level benefit the working environment?

A: A low noise level ensures a more comfortable and productive workspace, reducing auditory fatigue for operators working long shifts.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Paper Plate Making Machine' category

We mainly deal in Maharashtra, Gujarat, Madhya Pradesh and Rajasthan.

|

GREENTECH ENGINEERING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |