Greentech Engineering Hydraulic Single Die Paper Plate Making Machine

110000 INR/Piece

Product Details:

- Warranty One Year of Motor and Programmable Timer

- Click to View more

X

Greentech Engineering Hydraulic Single Die Paper Plate Making Machine Price And Quantity

- 01 Piece

- 110000 INR/Piece

Greentech Engineering Hydraulic Single Die Paper Plate Making Machine Product Specifications

- One Year of Motor and Programmable Timer

Greentech Engineering Hydraulic Single Die Paper Plate Making Machine Trade Information

- Yes

- All India

Product Description

Technical Specifications

| Model No. | GT-P12 |

| Die Size | 4"-15" |

| Production | 1200-1700 Pcs/Hr |

| Raw Material | 80 GSM to 450 GSM |

| Power Source | 220V, 50Hz |

| Electric Motor | 2HP |

| Power Consumption | 2 Unit/Hr |

| Oil Tank Capacity | 45 Ltrs |

| Weight | 250kg |

Efficient Plate Production

With a hydraulic single-die system, this machine delivers a swift production rate ideal for bulk manufacturing. Capable of processing 1,500 to 1,800 plates per hour, it helps businesses meet high demand efficiently while maintaining consistent quality standards.

Robust Construction

Constructed with mild steel and covered in a powder-coated finish, the machine resists corrosion and wear, extending its lifespan. The sturdy frame supports continuous operation and adds to its reliability in various working environments.

Versatile and User-Friendly Operation

Supporting paper weights from 80gsm to 300gsm, the semi-automatic model provides flexibility for different plate types. Intuitive controls make operation simple, and the 220V standard power supply ensures compatibility with common electrical systems.

FAQ's of Greentech Engineering Hydraulic Single Die Paper Plate Making Machine:

Q: How does the single-die hydraulic mechanism benefit plate production?

A: The hydraulic single-die mechanism ensures consistent pressure and uniform shaping, resulting in high-quality plates. It also improves speed and reduces manual labor compared to manual systems.Q: What types and weights of paper are suitable for use with this machine?

A: The machine is compatible with paper weights ranging from 80gsm to 300gsm. This allows the production of a variety of plate sizes and thicknesses, enhancing versatility in product offerings.Q: When should routine maintenance be performed on the machine?

A: Routine maintenance, such as lubricating moving parts and inspecting hydraulic components, should be performed monthly to ensure optimal performance and longevity of the machine.Q: Where is the ideal location to install this paper plate making machine?

A: It should be installed in a well-ventilated workspace with sufficient space for material handling and operator movement, preferably on a flat, stable surface to maintain safety and efficiency.Q: What is the process for operating this semi-automatic model?

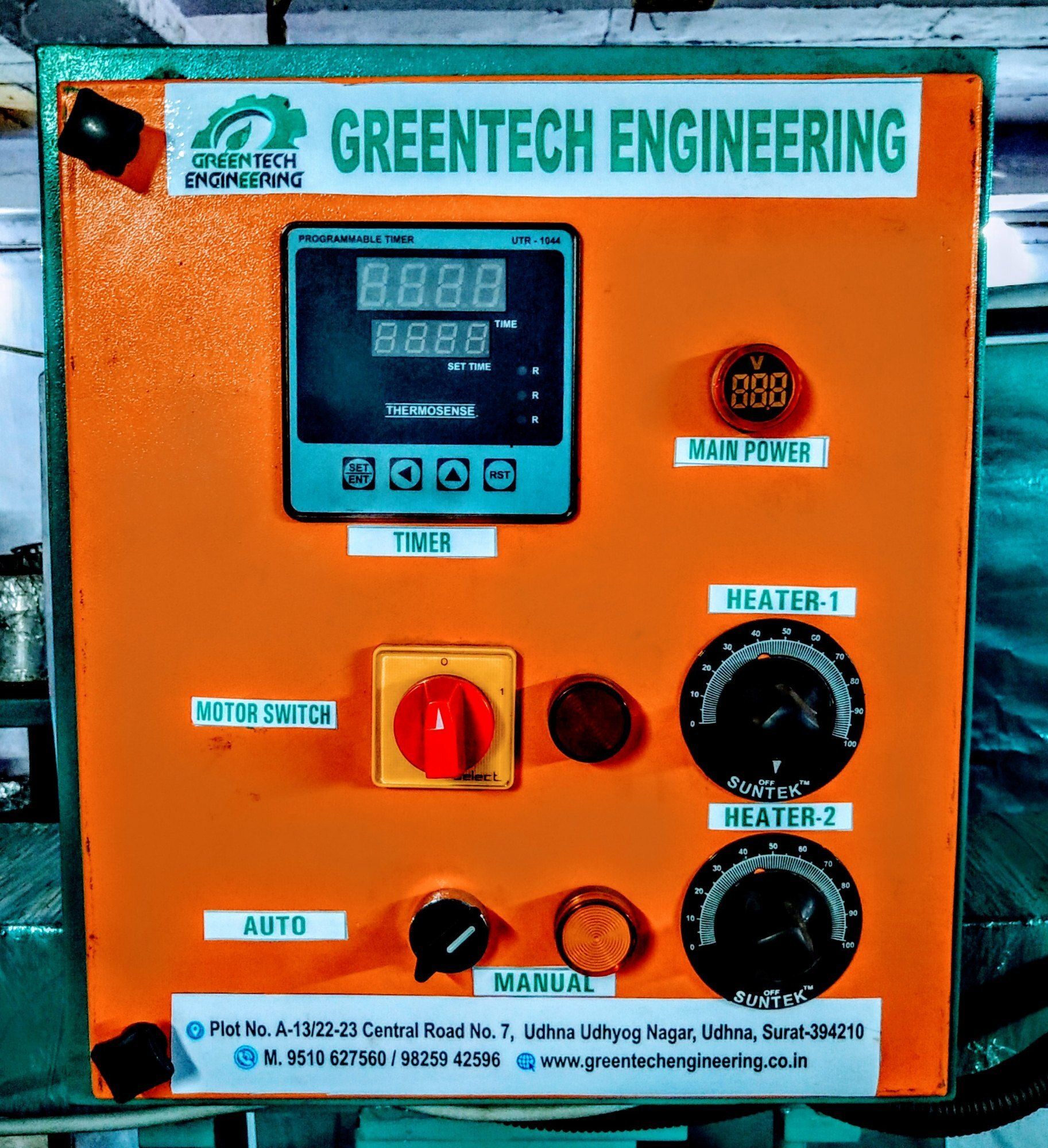

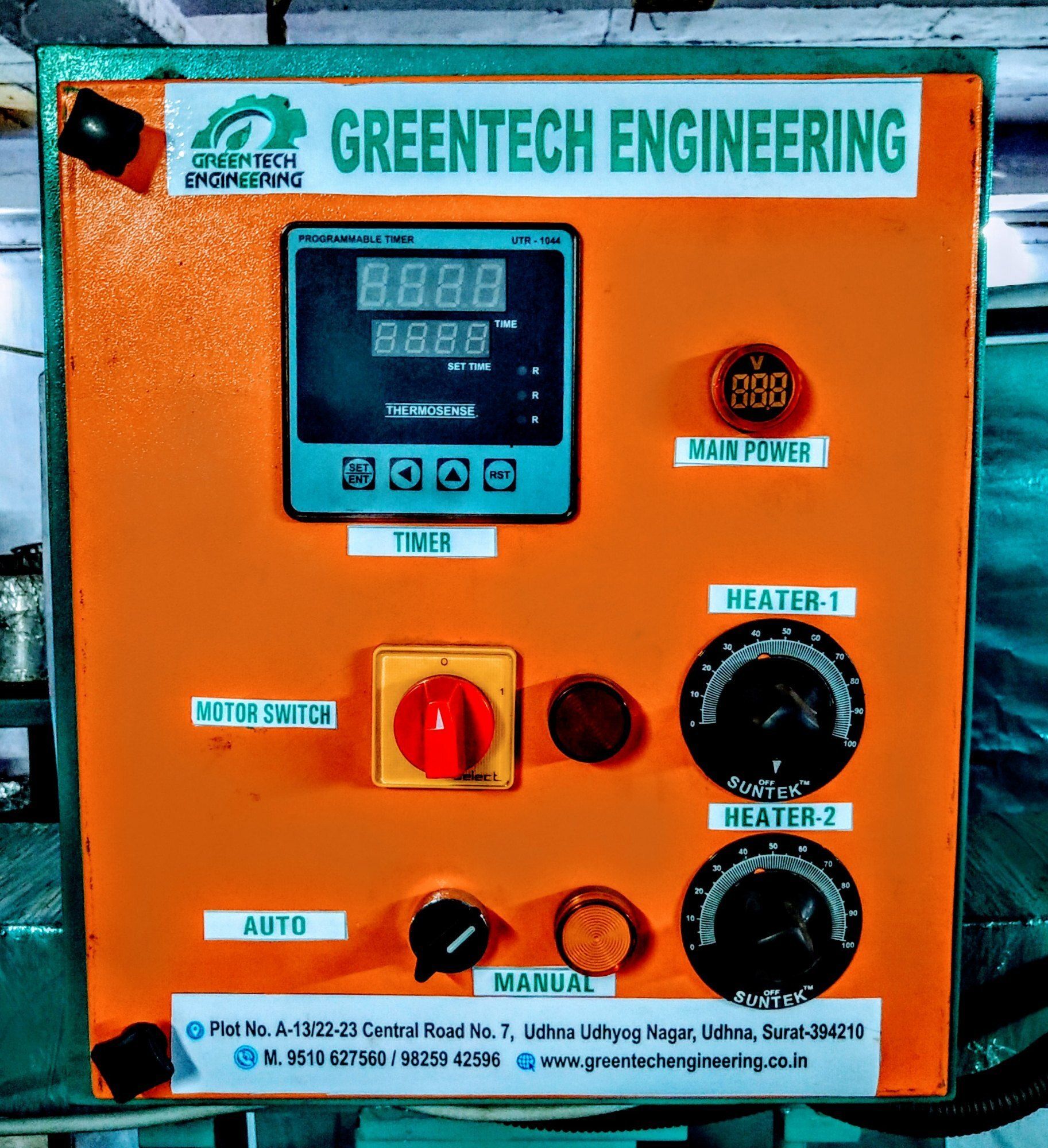

A: Simply feed the appropriate paper into the die area, set the programmable timer, and activate the hydraulic press using the controls. The machine handles pressing and shaping, outputting finished plates swiftly.Q: What warranty coverage is included with this purchase?

A: The machine includes a one-year warranty covering the 1HP induction motor and programmable timer, ensuring peace of mind for buyers regarding key components.Q: How does automation in this model improve user experience and productivity?

A: The semi-automatic operation minimizes manual intervention, simplifying usage and increasing output. Automated pressing and plate ejection also enhance safety and reduce operational fatigue for workers.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Paper Plate Making Machine' category

We mainly deal in Maharashtra, Gujarat, Madhya Pradesh and Rajasthan.

|

GREENTECH ENGINEERING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |