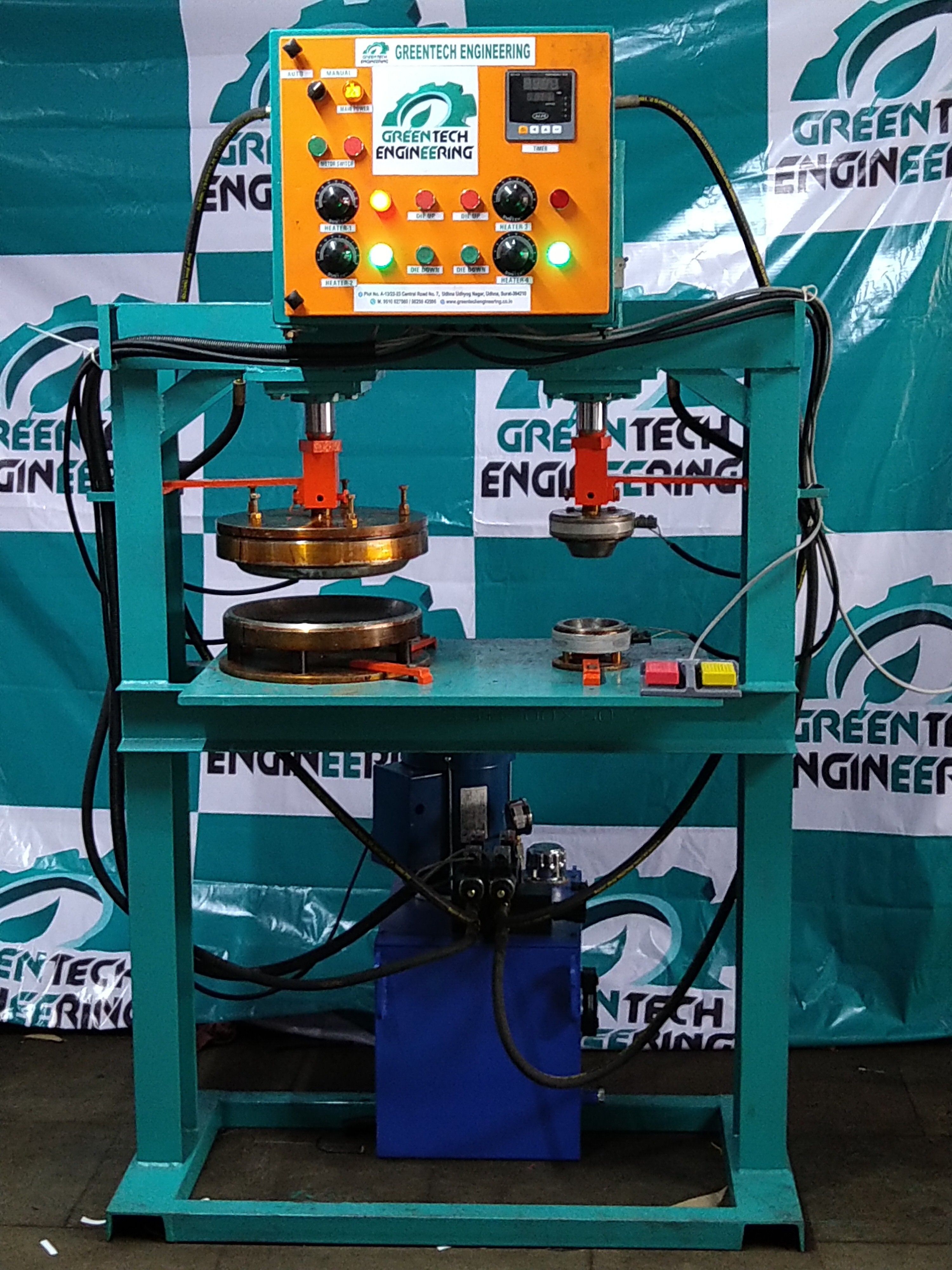

Plate Making Machine

180000.0 INR/Piece

Product Details:

X

Plate Making Machine Price And Quantity

- 180000.0 INR/Piece

- 1 Piece

Plate Making Machine Trade Information

- 100 Piece Per Month

- 1 Week

Product Description

Technical Specifications

| Model No. | GT-P09 |

| Die Size | 4-18 |

| Production | 2700-3000 Pcs/Hr |

| Raw Material | 80 GSM to 450 GSM |

| Power Source | 220V, 50Hz |

| Electric Motor | 2HP |

| Power Consumption | 2.5-3 Unit/Hr |

| Oil Tank Capacity | 45 Ltrs |

| Weight | 350kg |

Free Accessories

- Heater Set of Free Dies

- Ptfe Sheet = 1

- Die Connector = 8

- Spanner Set

- Rubber Pad

Dual Shape Capability

Catering to diverse dining and packaging needs, this plate making machine offers both round and square plate output. This flexibility allows businesses to cater to varied customer preferences with a single investment.

Robust Build for Longevity

Built with a sturdy body and powder-coated finish, the machine resists corrosion and daily wear. Its fixed base and air-cooled system further add to the machine's durability, ensuring stable and efficient operation in any production environment.

FAQ's of Plate Making Machine:

Q: How does the manual feeding process work in this plate making machine?

A: The manual feeding method requires operators to place raw materials into the machine by hand, allowing intuitive control over the plate-making process and ensuring material is positioned correctly before each production cycle.Q: What are the main advantages of having round and square plate shape options?

A: Offering both round and square plate shapes allows users to produce plates suitable for various meals and events, expanding business opportunities and meeting diverse customer requirements without the need for multiple machines.Q: When should the emergency stop safety feature be used?

A: The emergency stop should be activated immediately if there is any operational anomaly, maintenance requirement, or risk to user safety, instantly halting all machine functions for thorough inspection.Q: Where is this plate making machine manufactured and available for supply?

A: This machine is manufactured, supplied, exported, and imported from India, making it accessible for domestic and international businesses seeking quality plate making solutions.Q: What is the benefit of the air-cooled cooling system in this machine?

A: The air-cooled system efficiently maintains the machine's operating temperature, preventing overheating during extensive use and contributing to consistent performance and reduced maintenance needs.Q: How does the sturdy, fixed-base design impact the plate-making process?

A: The sturdy body with a fixed base ensures the machine remains stable during operation, minimizing vibration, reducing noise levels, and enhancing the accuracy and safety of plate production.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Plate Making Machine' category

We mainly deal in Maharashtra, Gujarat, Madhya Pradesh and Rajasthan.

|

GREENTECH ENGINEERING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |