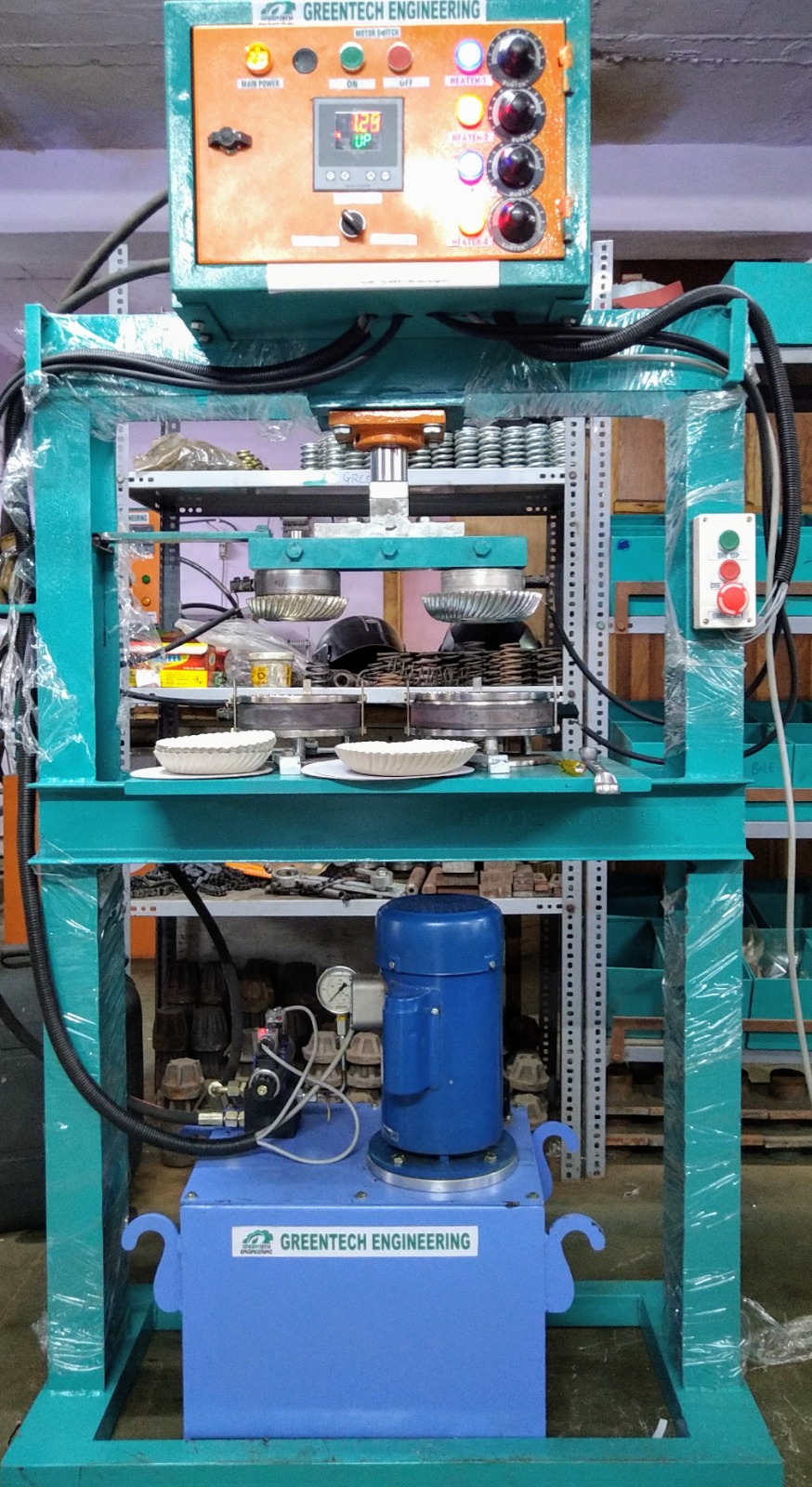

Die Paper Plate Making Machine

120000 INR/Piece

Product Details:

- Warranty One year of Motor and Programmable Timer

- Click to View more

X

Die Paper Plate Making Machine Price And Quantity

- 120000 INR/Piece

- 01 Piece

Die Paper Plate Making Machine Product Specifications

- One year of Motor and Programmable Timer

Die Paper Plate Making Machine Trade Information

- 40 - 50 Piece Per Month

- 5-7 Days

- Yes

- Cartoon Box(India) Wooden Box(Out of India)

- All India

Product Description

Technical Specifications

| Model No. | GT-P10 |

| Die Size | 4-15(Up to 9 Two Die) |

| Production | 1900-2700 Pcs/Hr |

| Raw Material | 80 GSM to 450 GSM |

| Power Source | 220V, 50Hz |

| Electric Motor | 2HP |

| Power Consumption | 2-2.5 Unit/Hr |

| Oil Tank Capacity | 45 Ltrs |

| Weight | 300kg |

Free Accessories

- Heater Set of Free Dies

- Ptfe Sheet = 1

- Die Connector = 4

- Spanner Set

- Rubber Pad

Robust and Reliable Construction

Manufactured with a heavy-duty frame and a durable powder-coated finish, this machine withstands rigorous daily operation. Its robust design is ideal for busy production environments, ensuring long-term reliability for exporters, importers, suppliers, and manufacturers in India.

Versatility in Plate Sizes

Equipped with interchangeable molds, the machine accommodates various tray sizes. This flexibility enables users to cater to diverse market demands and adapt quickly to new requirements without investing in multiple machines.

Safety and Efficiency Prioritized

The machine offers overheating protection and low noise output, assuring a safe and comfortable working environment. With a 1 HP motor and semi-automatic operation, users benefit from consistent plate output and minimized maintenance challenges.

FAQ's of Die Paper Plate Making Machine:

Q: How does the semi-automatic operation of the Die Paper Plate Making Machine work?

A: The semi-automatic operation means that while major functions like pressing are automated, loading of paper sheets is done manually. After manually placing the paper, the hydraulic press forms the plate using the specified mold.Q: What sizes of paper plates can be produced with this machine?

A: The machine is equipped with interchangeable molds, allowing you to produce disposable plates in a variety of sizes according to market requirements.Q: When should I perform routine maintenance on the machine?

A: Routine maintenance should be conducted as per the user manual, typically after every production cycle or at least once a week to ensure all mechanical and hydraulic components are functioning smoothly.Q: Where can this machine be installed for operation?

A: This machine can be set up in medium to large workshops or manufacturing units equipped with sufficient electrical supply and safe ventilation. Its heavy-duty construction supports industrial use.Q: What is the process for changing the die molds for different plate sizes?

A: To change dies, switch off the machine, safely detach the current mold, then securely attach the new mold according to the instructions provided. This quick-change feature enables smooth transition between production batches.Q: How does the machine enhance safety during operation?

A: The Die Paper Plate Making Machine is fitted with overheating protection to reduce the risk of damage or accidents. Its low noise level and robust build further contribute to a safer working environment.Q: What are the key benefits of using this machine for disposable plate manufacturing?

A: Key benefits include its high output (220-250 plates per hour), low noise operation, adaptability to different plate sizes, and durable construction. Its design maximizes productivity while minimizing safety risks and maintenance needs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Paper Plate Making Machine' category

We mainly deal in Maharashtra, Gujarat, Madhya Pradesh and Rajasthan.

|

GREENTECH ENGINEERING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |