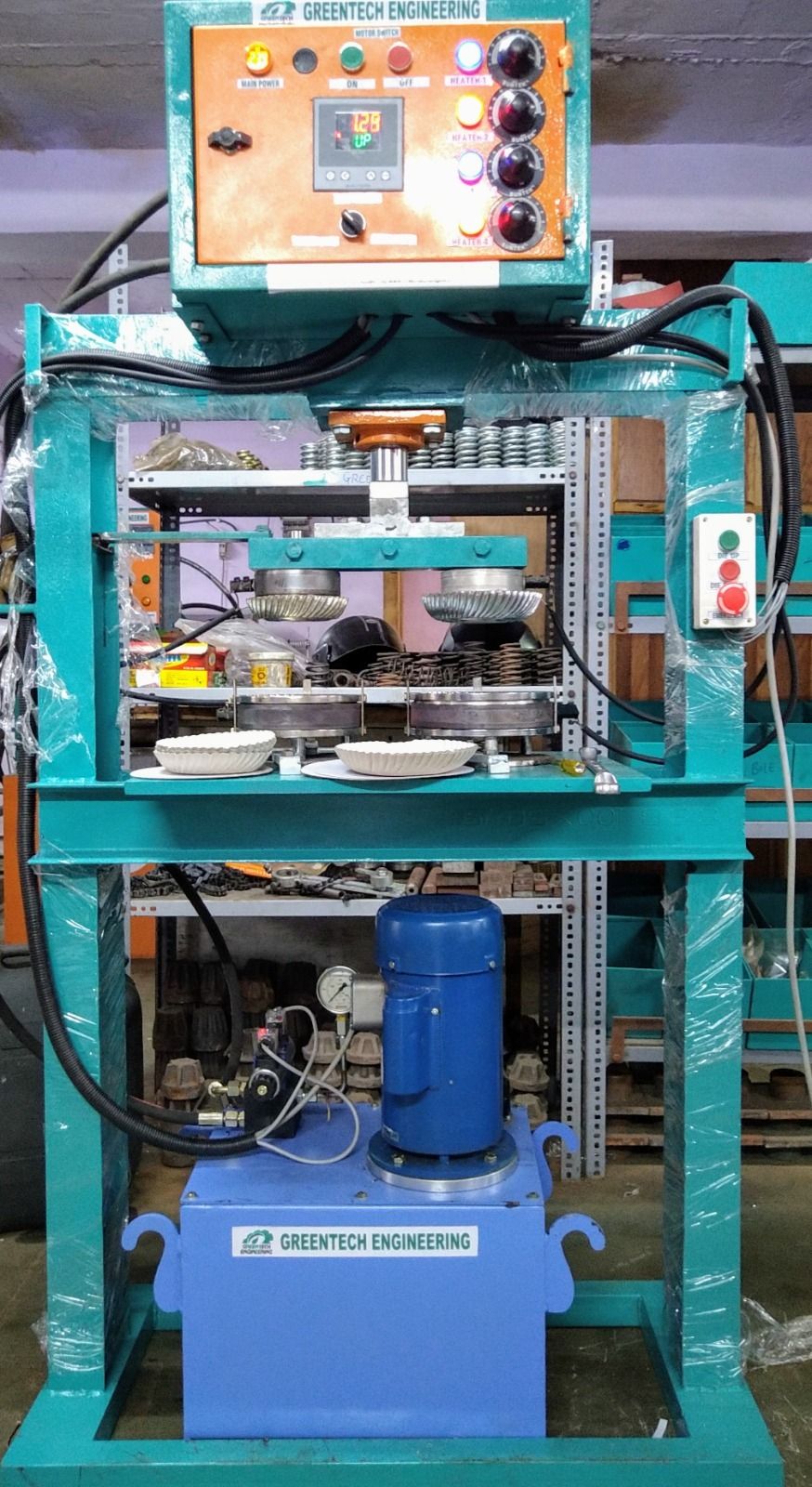

Nasta Dish Making Machine

115000 INR

Product Details:

- Warranty One year of Motor and Programmable Timer

- Click to View more

X

Nasta Dish Making Machine Price And Quantity

- 115000 INR

- 01 Piece

Nasta Dish Making Machine Product Specifications

- One year of Motor and Programmable Timer

Nasta Dish Making Machine Trade Information

- Western Union, Paypal, Cash in Advance (CID), Cheque

- 5-7 Days

- Yes

- All India

Product Description

Technical Specifications

| Model No. | GT-P10 |

| Die Size | 4"-15"(Up to 9" Two Die) |

| Production | 1900-2700 Pcs/Hr |

| Raw Material | 80 GSM to 450 GSM |

| Power Source | 220V, 50Hz |

| Electric Motor | 2HP |

| Power Consumption | 2-2.5 Unit/Hr |

| Oil Tank Capacity | 45 Ltrs |

| Weight | 300kg |

Free Accessories

| Heater Set of Free Dies |

| Teflon Sheet = 1 |

| Die Connector = 4 |

| Spanner Set |

| Rubber Pad |

Automatic Feeding for Effortless Production

Experience consistent productivity with the auto feeding system. Designed to streamline the dish-making process, the machine minimizes manual intervention and optimizes workflow. This feature aids in reducing production time and heightening efficiency, making it ideal for businesses aiming for large-scale output.

Robust Hydraulic Operation

Benefit from smooth, controlled movements courtesy of hydraulic functionality. This enhances machine precision and reduces wear-and-tear, ensuring the Nasta Dish Making Machine delivers dependable performance under heavy-duty use. Hydraulic operation also supports safety, keeping operators secure during production.

FAQ's of Nasta Dish Making Machine:

Q: How does the auto feeding system work on the Nasta Dish Making Machine?

A: The auto feeding system automatically moves material into the forming area, eliminating manual handling and boosting production speed. It ensures consistent input, which helps maintain uniformity in dish quality throughout the manufacturing process.Q: What safety features are included with this machine?

A: The Nasta Dish Making Machine incorporates both hand safety features and foot pedal operation. These elements work together to reduce accident risks by allowing hands-free activation and providing protective mechanisms during use.Q: When should regular maintenance be performed and what does it involve?

A: Routine maintenance is recommended every few months, depending on usage. The machine's low maintenance design means tasks typically involve checking hydraulic fluids, inspecting moving parts, and ensuring the auto feeding system operates smoothly.Q: Where can this dish making machine be installed and operated?

A: With its support for single-phase power and compact heavy-duty build, the machine can be conveniently installed in small workshops, commercial kitchens, and manufacturing units across India.Q: What is the process of creating dishes with this machine?

A: The process begins by loading raw material into the hopper, which is automatically fed to the die area. The hydraulic system shapes the material using the included die, and completed dishes are released for collection, all controlled via the foot pedal.Q: What benefits does this machine offer to exporters and suppliers in India?

A: Exporters and suppliers gain advantages such as increased output, improved safety, and minimal downtime due to the machine's low maintenance requirements and reliable performance. The one-year warranty offers additional peace of mind for business operations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Fully Automatic Paper Plate Making Machine' category

We mainly deal in Maharashtra, Gujarat, Madhya Pradesh and Rajasthan.

|

GREENTECH ENGINEERING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |