Disposable Plate Making Machine

120000 INR/Piece

Product Details:

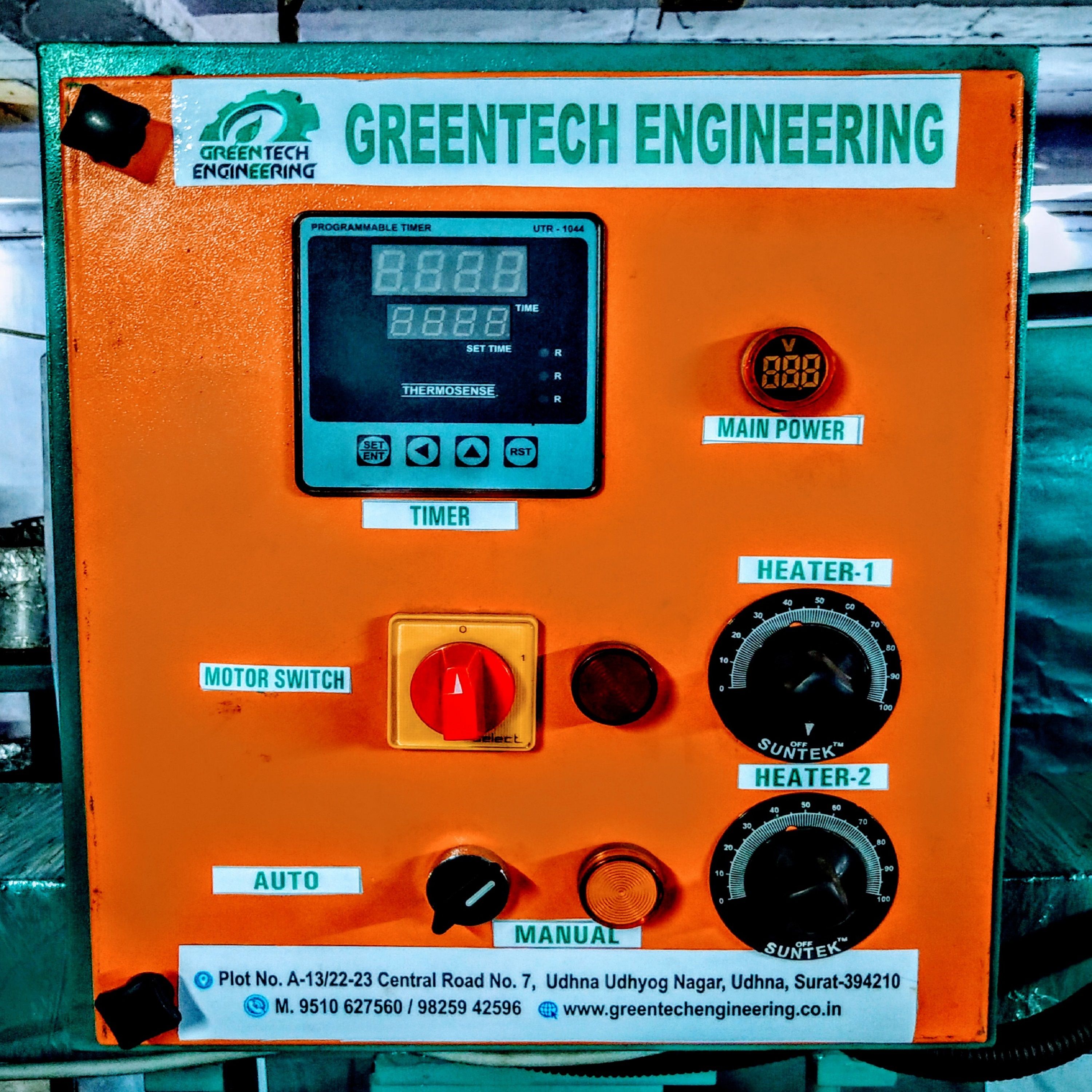

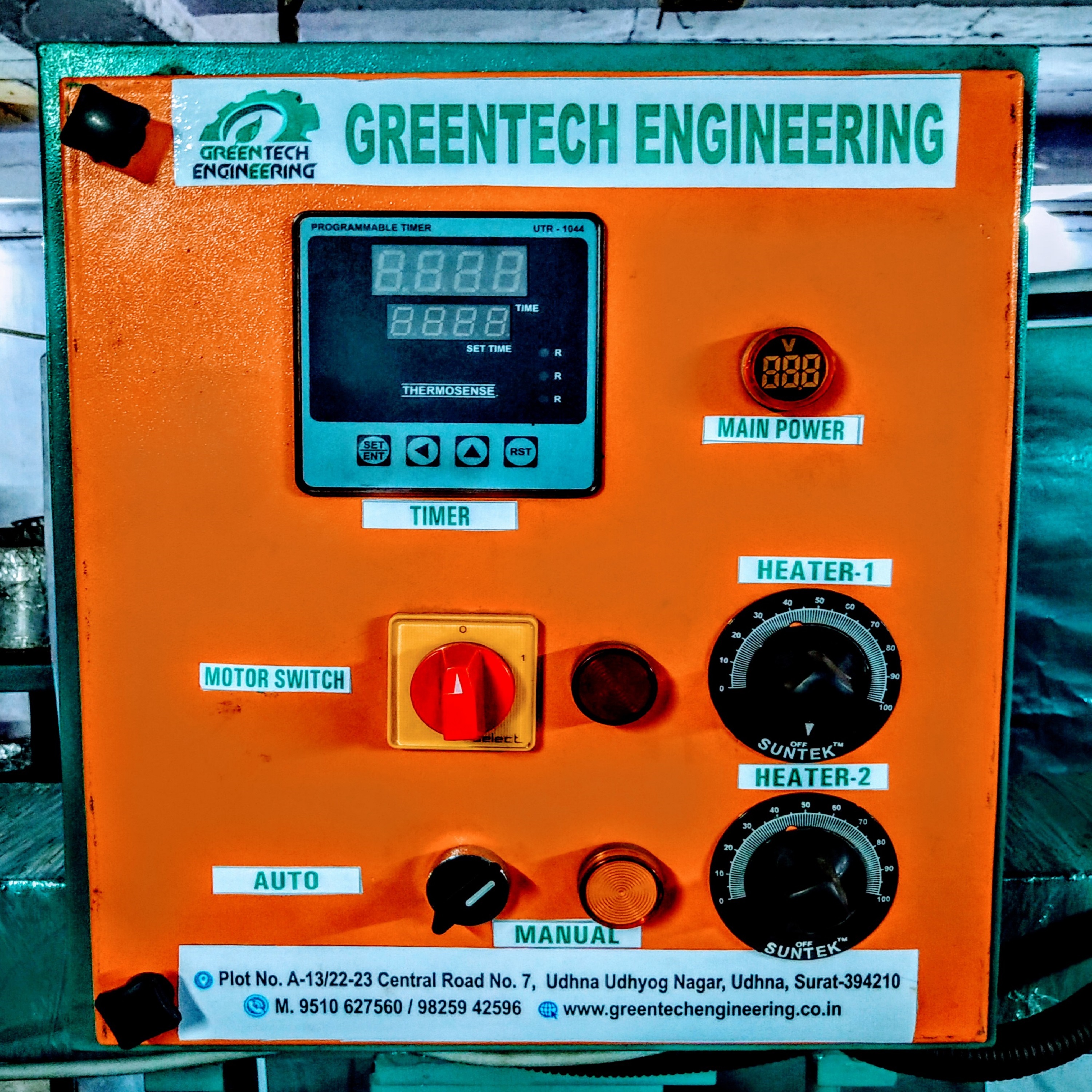

- Control System Human Machine Interface

- Warranty One year of Motor and Programmable Timer

- Click to View more

X

Disposable Plate Making Machine Price And Quantity

- 120000 INR/Piece

- 01 Piece

Disposable Plate Making Machine Product Specifications

- One year of Motor and Programmable Timer

- Human Machine Interface

Disposable Plate Making Machine Trade Information

- 50-60 Piece Per Month

- 5-7 Days

- Yes

- All India

Product Description

Technical Specifications

| Model No. | GT-P10 |

| Die Size | 4-15(Up to 9Two Die) |

| Production | 1900-2700 Pcs/Hr |

| Raw Material | 80 GSM to 450 GSM |

| Power Source | 220V, 50Hz |

| Electric Motor | 2HP |

| Power Consumption | 2-2.5 Unit/Hr |

| Oil Tank Capacity | 45 Ltrs |

| Weight | 300kg |

Free Accessories

- Heater Set of Free Dies

- Ptfe Sheet = 1

- Die Connector = 4

- Spanner Set

- Rubber Pad

Advanced Hydraulic Technology

The hydraulic die system ensures precise cutting and molding, supporting a high output rate. This feature caters to both paper and leaf plate production, providing flexibility across various materials. The heavy-duty steel frame adds stability, ensuring long-term operation and minimal maintenance concerns.

Effortless Operation and Control

Single phase power compatibility and a user-friendly Human Machine Interface (HMI) make the plate making process efficient and straightforward. Operators can monitor, control, and adjust machine settings with ease, ensuring consistent product quality and streamlined workflow for manufacturers.

Comprehensive Safety and Warranty

Safety is prioritized with the inclusion of an emergency stop button, providing immediate shutdown in case of emergencies. The one-year warranty covers the motor and programmable timer, giving buyers confidence in the machine's reliability for business use in the export and supply sectors.

FAQ's of Disposable Plate Making Machine:

Q: How does the fully automatic operation benefit plate production?

A: The fully automatic system minimizes manual intervention, streamlining the entire manufacturing process. This results in higher efficiency, consistent plate quality, and increased production rates, enabling businesses to meet larger demands with reduced labor requirements.Q: What types of materials are compatible with this disposable plate making machine?

A: This machine is designed to handle both paper and organic leaf materials, allowing manufacturers to produce eco-friendly plates in various sizes ranging from 4 to 14 inches.Q: When should I perform regular maintenance on the equipment?

A: Routine maintenance, such as cleaning and inspection, should be conducted after each production cycle or at least once weekly. This schedule ensures optimal machine performance and longevity, especially under high output scenarios.Q: Where is this machine ideal for installation and use?

A: Thanks to its single phase power compatibility and robust construction, the machine is suitable for small-scale workshops as well as large manufacturing units. It's particularly effective for exporters, importers, manufacturers, and suppliers across India.Q: What is the process for operating the machine safely?

A: After configuring plate size and material type via the Human Machine Interface, load the chosen raw material and start the automatic cycle. The emergency stop button is readily accessible for immediate shutdown in case of an incident, upholding workplace safety.Q: How does the warranty support business owners?

A: The one-year warranty on the motor and programmable timer safeguards key components, minimizing downtime and ensuring smooth operation. It provides peace of mind for manufacturers and suppliers relying on consistent machine performance.Q: What are the main advantages of the heavy-duty steel frame?

A: The heavy-duty steel frame enhances structural strength and stability, enabling continuous, high-output production with reduced risk of wear and tear. This durability results in longer equipment lifespan and lower maintenance costs for operators.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Disposable Plate Making Machine' category

We mainly deal in Maharashtra, Gujarat, Madhya Pradesh and Rajasthan.

|

GREENTECH ENGINEERING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |