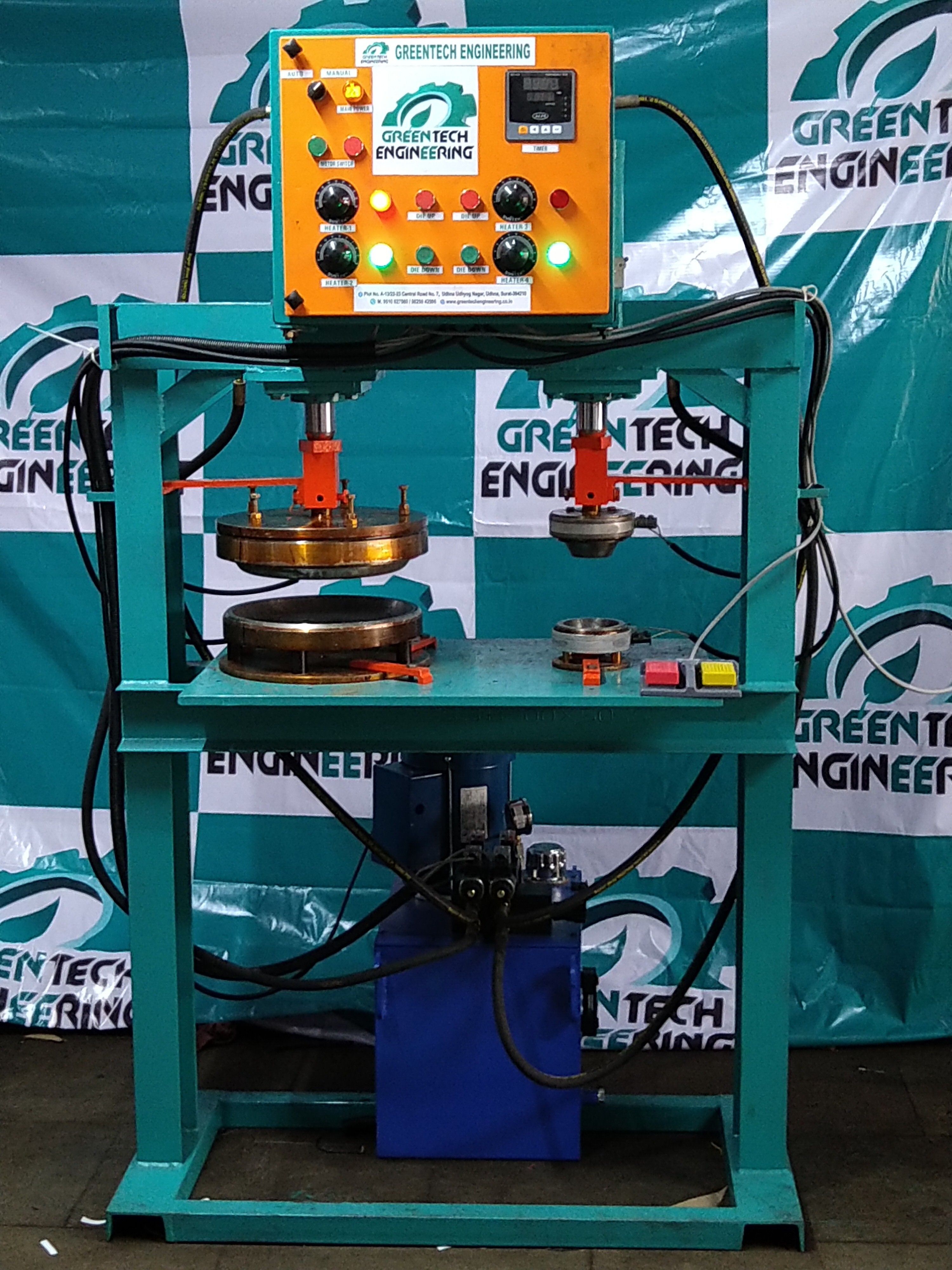

Buffet Plate Making Machine

165000 INR

Product Details:

- Warranty One year of Motor and Programmable Timer

- Click to View more

X

Buffet Plate Making Machine Price And Quantity

- 01 Piece

- 165000 INR

Buffet Plate Making Machine Product Specifications

- One year of Motor and Programmable Timer

Buffet Plate Making Machine Trade Information

- Western Union, Paypal, Cheque

- 5-7 Days

- Yes

- All India

Product Description

Technical Specifications

| Model No. | GT-P09 |

| Die Size | 4"-18" |

| Production | 2700-3000 Pcs/Hr |

| Raw Material | 80 GSM to 450 GSM |

| Power Source | 220V, 50Hz |

| Electric Motor | 2HP |

| Power Consumption | 2.5-3 Unit/Hr |

| Oil Tank Capacity | 45 Ltrs |

| Weight | 350kg |

Free Accessories

| Heater Set of Free Dies |

| Teflon Sheet = 1 |

| Die Connector = 8 |

| Spanner Set |

| Rubber Pad |

High-Capacity, Reliable Plate Production

Engineered for businesses that need efficiency, this Buffet Plate Making Machine can produce up to 2000 disposable buffet plates per hour. The double die design ensures rapid, simultaneous plate formation, making it ideal for large-scale suppliers and manufacturers looking to meet growing demand with consistent quality.

Advanced Safety and Control Features

Safety is paramount with the inclusion of an emergency stop switch, allowing immediate halting of operations in critical moments. The digital control panel provides precise command over machine settings, ensuring ease of use, monitoring, and adaptability to different production needs.

Durable Construction and Support

Constructed with a sturdy mild steel body, this fully automatic machine is built to endure rigorous industrial use. It comes with a one-year warranty on the motor and programmable timer, reflecting our commitment to long-term performance and customer satisfaction, whether you are an exporter, importer, manufacturer, or supplier.

FAQ's of Buffet Plate Making Machine:

Q: How does the fully automatic Buffet Plate Making Machine operate?

A: The Buffet Plate Making Machine works on a fully automatic basis using a heavy-duty induction motor and double die system. Simply load the raw material, configure the settings on the digital control panel, and the machine will automatically handle the rest-from feeding and forming to cutting and plate ejection.Q: What is the process for producing disposable buffet plates with this machine?

A: Production involves placing suitable raw materials in the feeder, setting desired parameters via the digital control panel, and allowing the automatic system to shape, cut, and eject up to 2000 buffet plates per hour through the double die setup.Q: When should the emergency stop switch be used?

A: The emergency stop switch is designed for safety and should be used to immediately halt all machine functions in case of a malfunction, maintenance need, or any unsafe situation during operation.Q: Where is this Buffet Plate Making Machine typically installed?

A: This machine is suitable for installation in manufacturing facilities, industrial production units, or supplier warehouses specializing in disposable buffet plate production, particularly by exporters and importers across India.Q: What usage benefits does the digital control panel provide?

A: The digital control panel offers intuitive operation and precise adjustment of production parameters, resulting in greater efficiency, reduced error, and easier monitoring. It streamlines machine setup and improves overall workflow for operators.Q: What are the main benefits of investing in this Buffet Plate Making Machine?

A: Investing in this machine offers high production rates, durability, reliable performance, enhanced safety features, and reduced manual intervention, making it a valuable asset for businesses looking to scale up disposable plate manufacturing.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Disposable Plate Making Machine' category

We mainly deal in Maharashtra, Gujarat, Madhya Pradesh and Rajasthan.

|

GREENTECH ENGINEERING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |